Boron Nitride Paste

The concentrated water-based Boron Nitride Paste still has good performance in the state of high dilution. It is used for the construction of dip-coated parts and can form a relatively hard coating after drying.

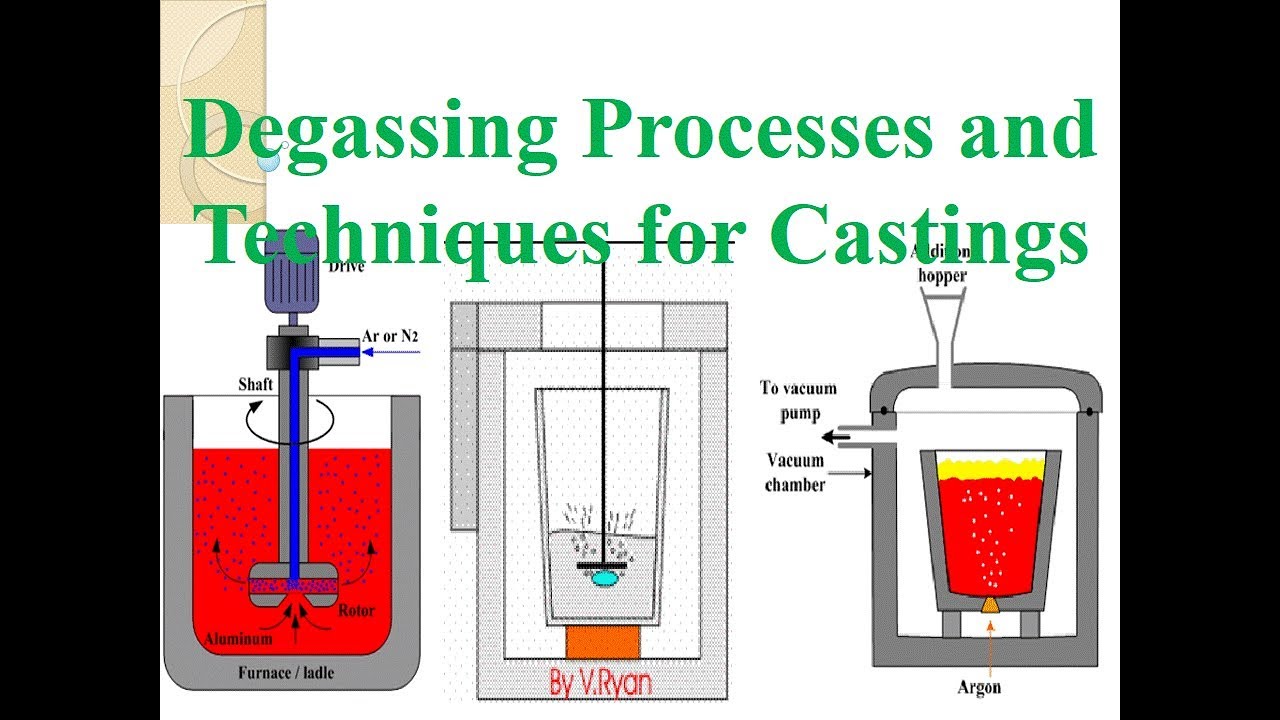

Therefore, when a harder coating is required (such as a moving element such as a graphite rotor) that is in contact with the melt, this coating is generally selected. Graphite, metal, ceramic, etc. are suitable for this coating.

How to use Boron Nitride Paste:

1.Clean the surface of the protected material.

2. Apply the diluted BN paint to the surface of the material with a sponge (or a brush or spray gun). Dilution multiple: material: water = 1: 5 ~ 6, customers can adjust as needed.

3. After coating, bake at a temperature of about 300 ℃, and it can be used after the coating is dried.

4. For the inaccessible local coating (such as the inner wall of a thin tube), the coated part can be immersed in the diluted BN coating, and the excess coating will naturally flow out after being taken out and used after drying (this method is only applicable to metal parts)

Note: the coating should be uniform, do not make BN aggregate on the surface, that is, do not apply too thick.

Boron Nitride Paste product advantages:

High temperature stability and non-stick aluminum.

Can be applied on hot or cold surfaces. After drying, the coating can be treated, smoothed and polished with a dry soft cloth or paper.

Special formula, water-based matrix, easy to use.

It is environmentally friendly coating, non-toxic and pollution-free.

Packaging and storage:

5kg / drum, 20kg / carton.

Store tightly closed in a cool warehouse. The ambient temperature is not lower than 10 ° C.