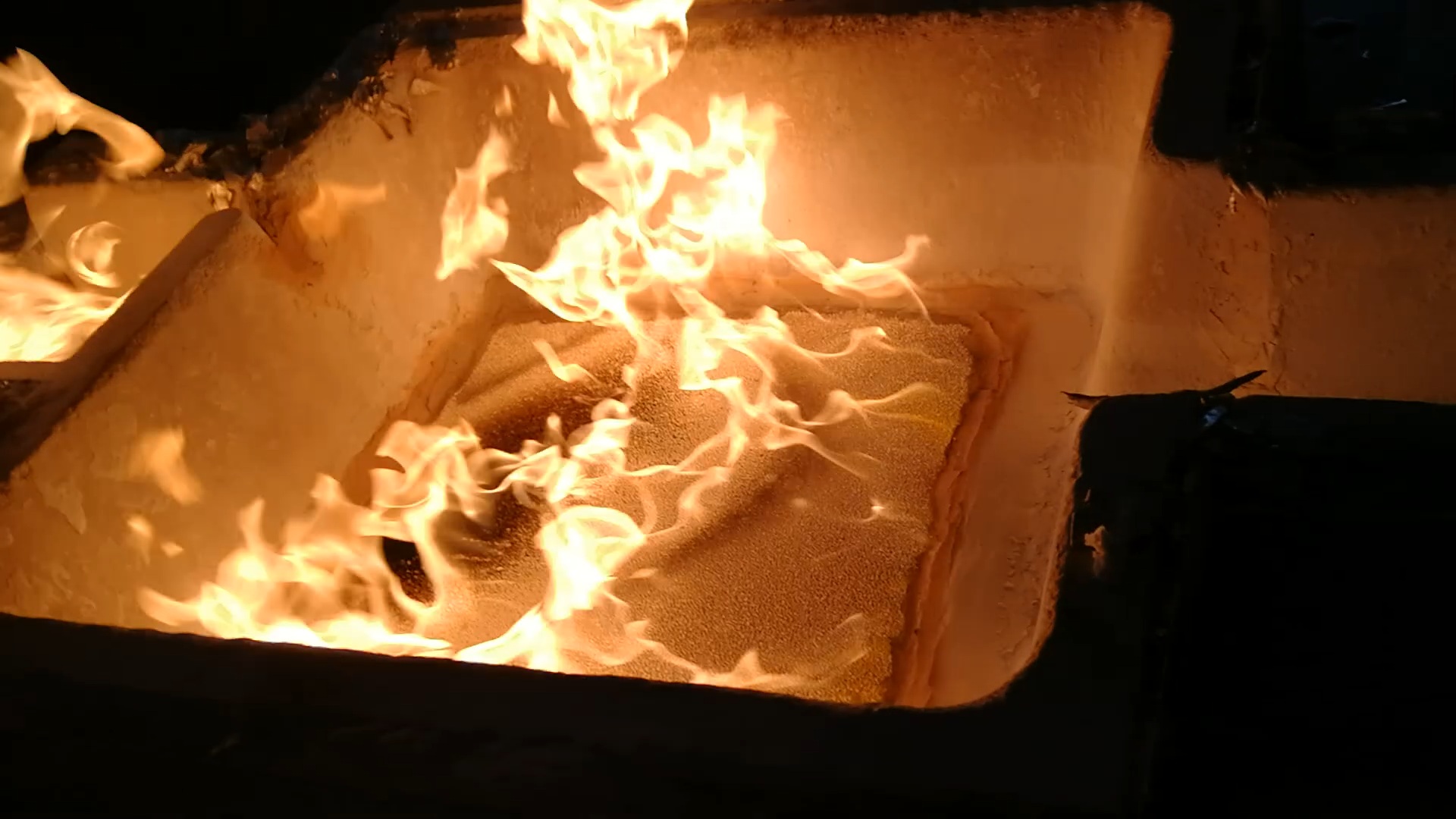

Aluminum Cff is the last purification process in modern aluminum melt purification process.

Prior to this, after flux refining in the furnace, standing, medium and non-medium adsorption, etc., although 60% to 80% of the inclusions and gases have been removed, the melt is still dispersed and distributed in finer particles (general particle size) <15um) Inclusions (including secondary inclusions caused by chute and middle bag).

In order to obtain high-performance aluminum products, these fine inclusions must be gathered and separated by adsorption.

Compared with other purification methods, the filtration method has become the preferred process for the terminal purification treatment of aluminum melt because of its low energy consumption, convenient operation, high impurity removal efficiency and less secondary pollution.

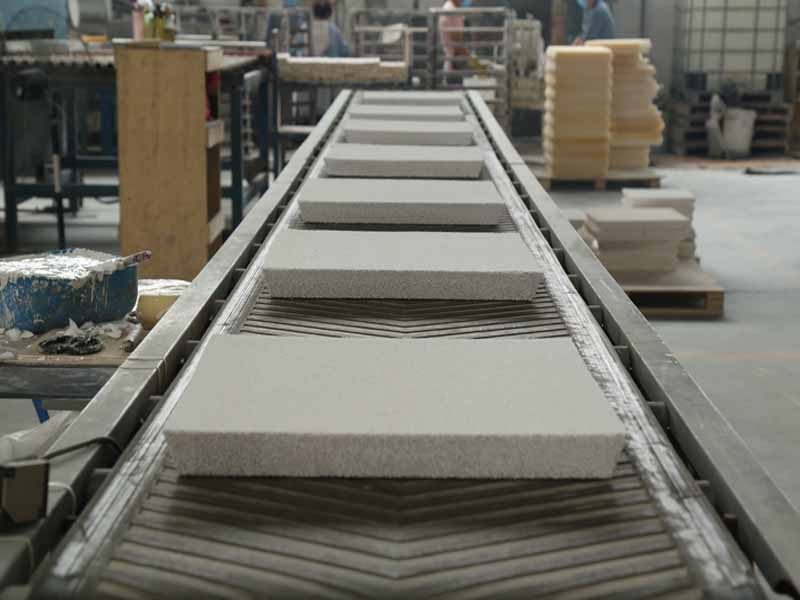

Aluminum Cff is currently the most widely used Aluminium Cff for aluminum melt filtration. Its advantages are high porosity, high filtration efficiency, convenient replacement, low cost, and strong adaptability. It can filter solid inclusions as well as part of liquid inclusions. The disadvantages are low high-temperature strength, short life, and small filtration capacity.