Aluminum Casting Using Ceramic Foam Filter

Aluminum Casting Using Ceramic Foam Filter is designed for filtration of aluminum and aluminum alloys.

It is characterised by excellent stability and resistance towards heat shocks.

The complexity of filters is not damaged during the casting process.

With their excellent resistance to attack and corrosion from molten aluminum, they can effectively remove inclusions, reduce trapped gas and provide laminar flow.

Clearner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Aluminum Casting Using Alumina Ceramic Foam Filter are normally applied by placing them into a filter bowl.

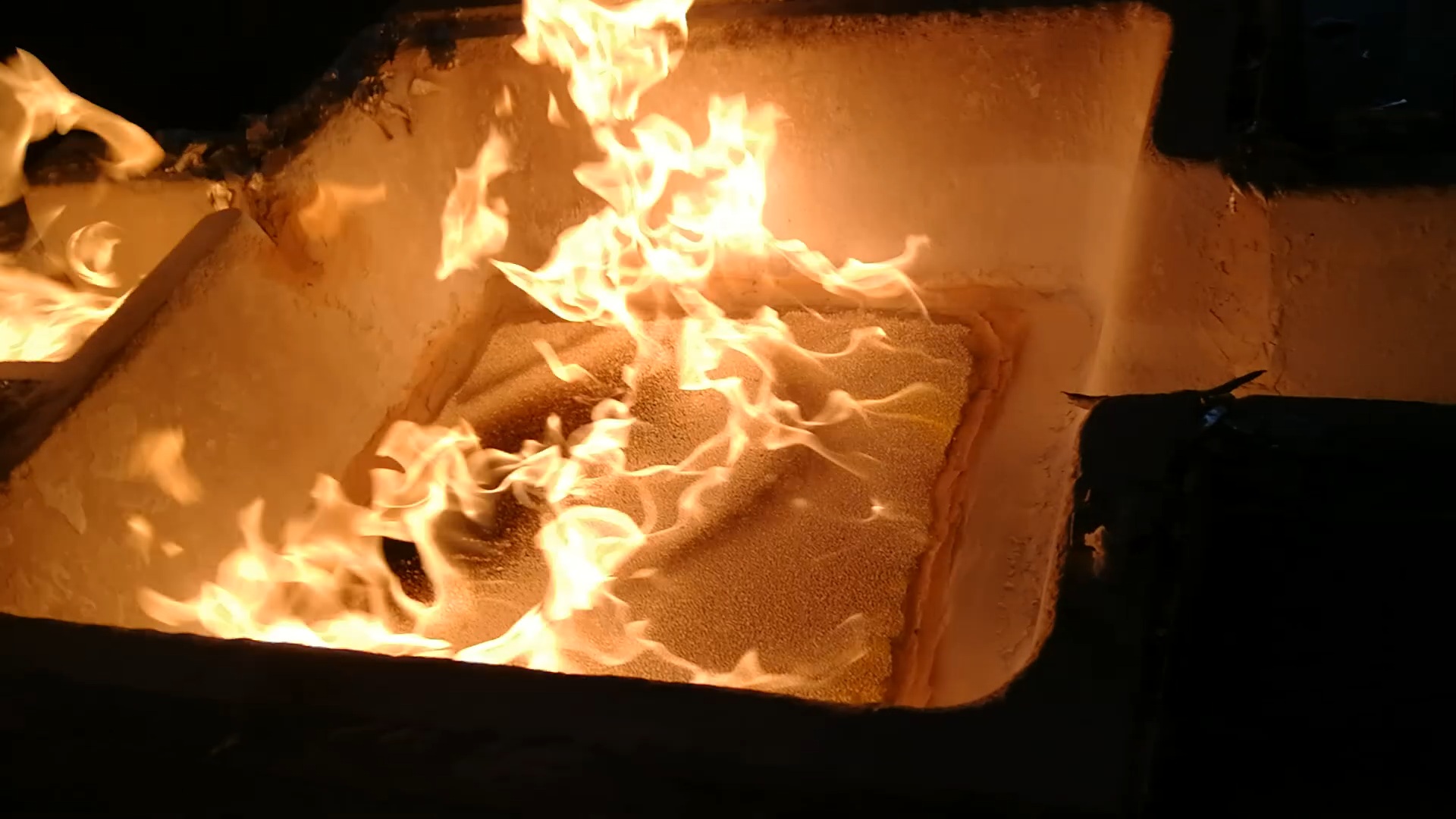

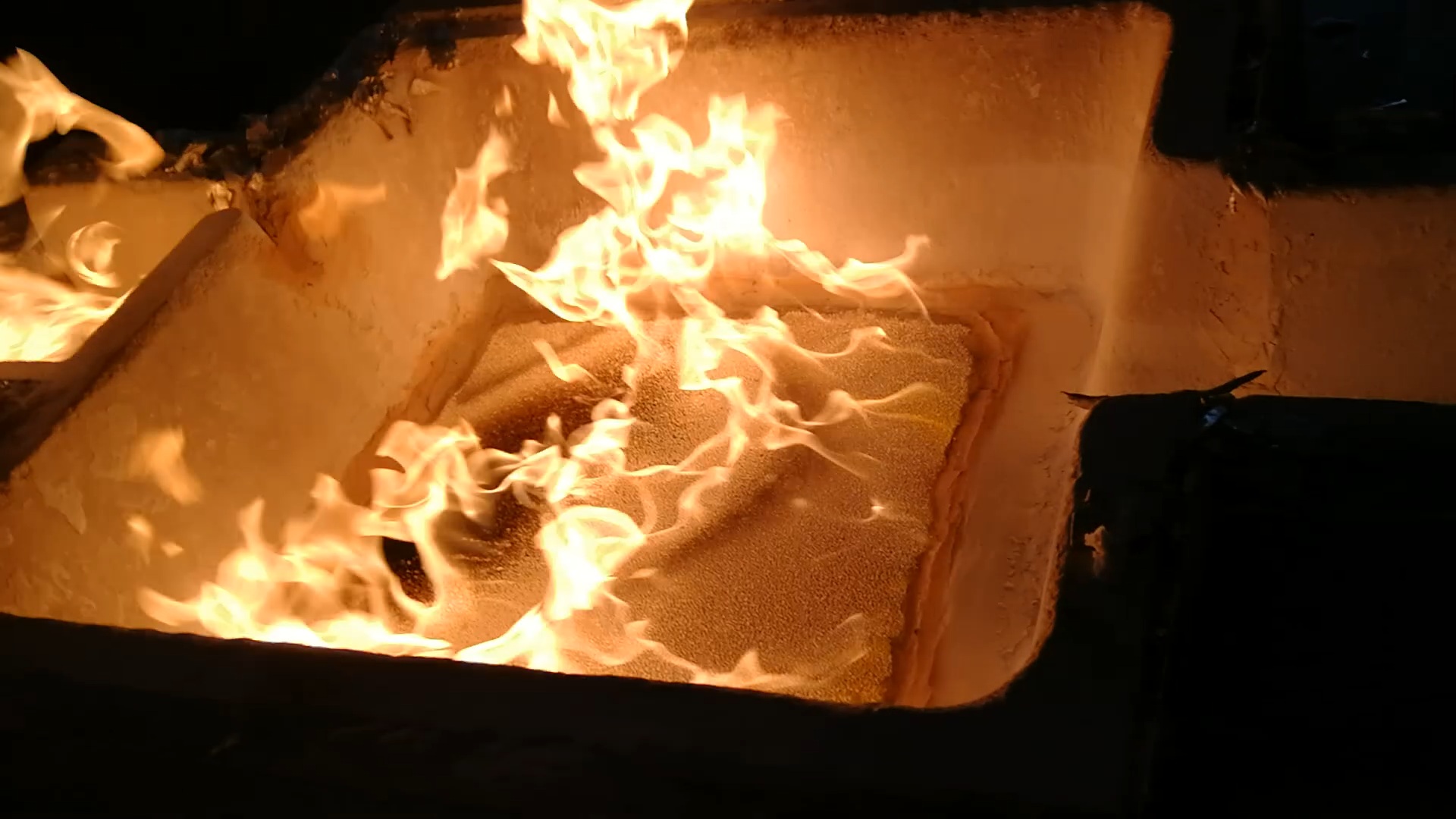

It is important to pre-heat both filter and bowl before use. During pre-heat care must be taken to control both heat up rate and temperature distribution. This minimizes thermal shock and stresses in the filters and filter bowl refractory.

Aluminum Casting Using Ceramic Foam Filter is increasingly being used in aluminum industry these days. These are special filters made using materials like silica carbide and aluminum oxide to give them structural stability and to ensure resistance to thermal shocks.

Ceramic foam filter is able to remove oxides from the surface of aluminum and thus increase casting quality. More and more aluminum sheets and foil manufacturers are today using AdTech filters.

After passing through the AdTech Filter, the impurities as well as gaseous substances present in the liquid or molten metal can pass into the moulds. This will ensure that the metal cast is in purer form. When the metal passes through the zirconia ceramic foam filter, the filter is able to extract the impurities as well as the gases and liquid contents in more efficient manner. This is because the extruded filter form is having regular shaped honeycomb gaps, through which the metal in molten form can pass with ease.