Ceramic Foam Filter for Aluminum Casting Foundry is a modern material in demand in many industrial fields. It is made from highly dispersed mineral powders, as well as from liquid foams; has a porous structure.

The unique properties of this material make it simply indispensable in many industries. Ceramic foam material has low thermal conductivity and high heat resistance.

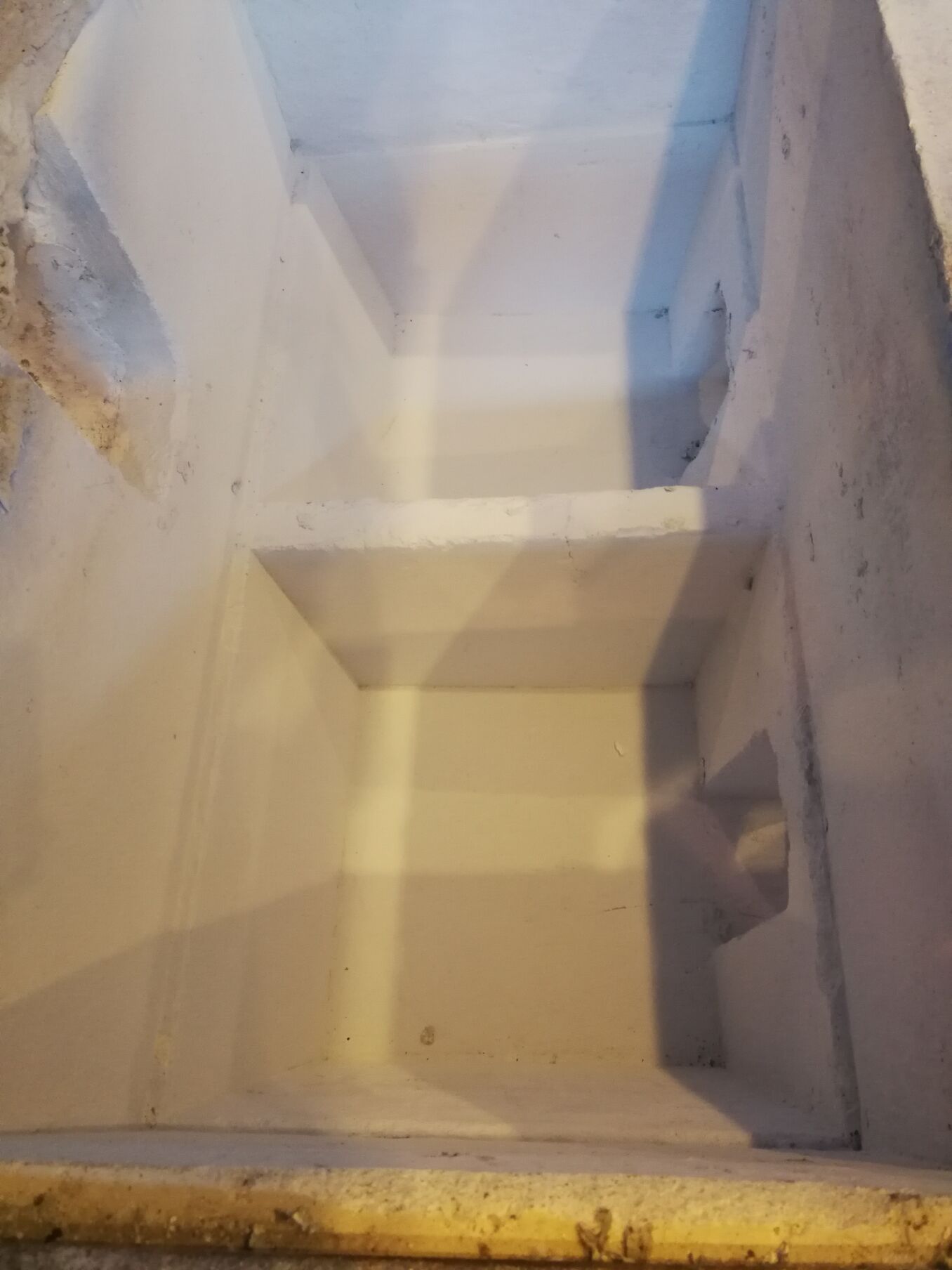

Ceramic foam filters (PFK) are used to separate molten metal from mechanical impurities. PFC is characterized by the so-called three-dimensional structure of mutually open pores. This structure allows you to maximize the filtering process.

Ceramic foam filters are in demand in the metallurgical industry, since ceramic foam has a number of unique properties. Modern foundry is simply not possible without the use of this type of filtering.

The use of foam ceramic filters makes it possible

improve the quality of castings,

significantly reduce production costs,

simplify gate systems,

optimize casting speed,

improve the mechanical characteristics of castings,

increase the operational properties of castings,

increase the density of castings,

reduce the amount of marriage, etc.