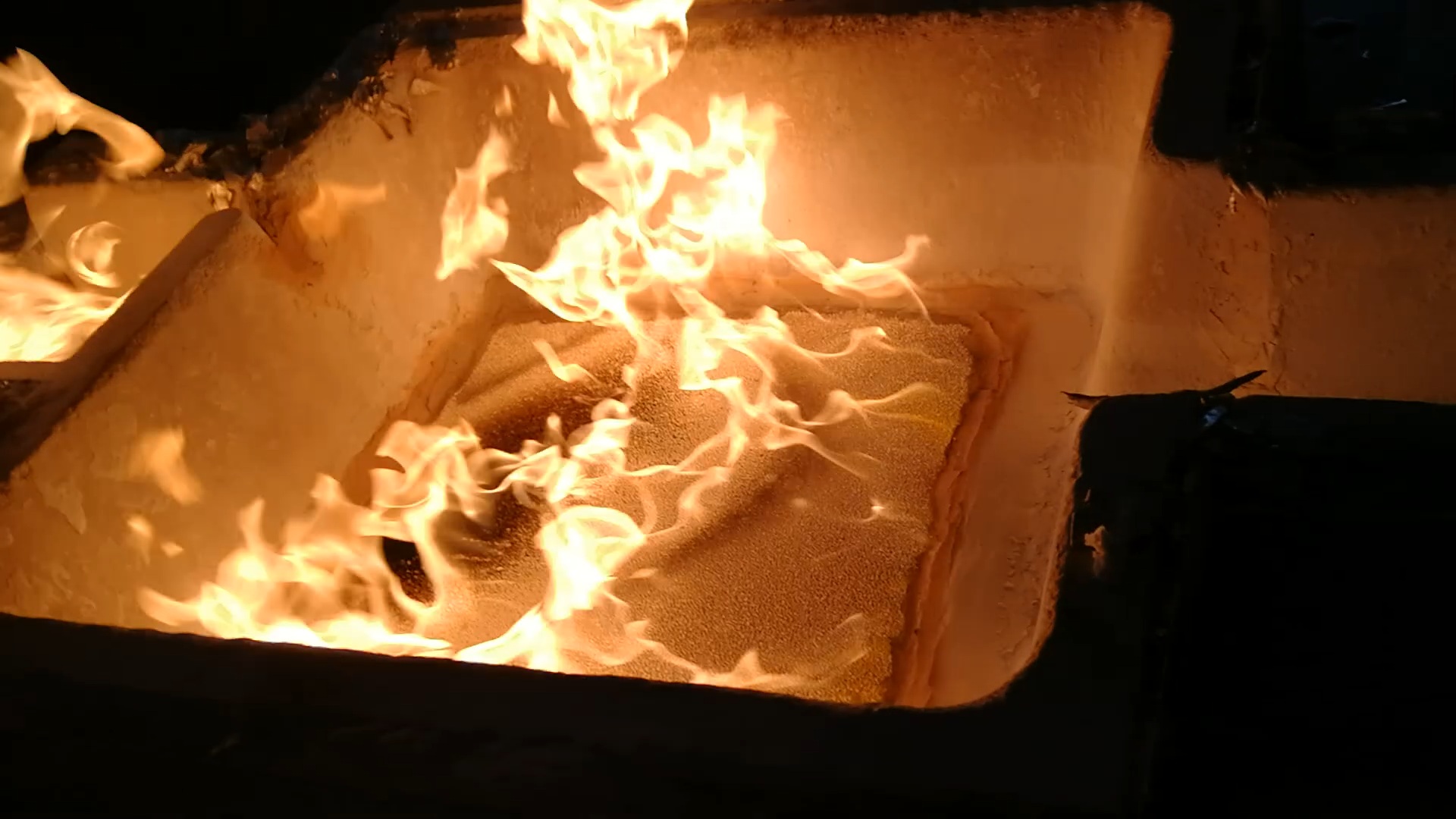

Aluminum Casting Filters use a three-dimensional network structure and connected pores of organic foam as the carrier, invade it into the special ceramic slurry with thixotropy, and adopt a special roll extrusion process to make the ceramic slurry evenly spread on the skeleton of the carrier , And then dried and cured and then baked at high temperature.

Aluminum Casting Filters are made of aluminum oxide. After adjusting the formula and process parameters, they are also suitable for silicon carbide, aluminum oxide and other materials.

Due to the characteristics of aluminum, aluminum alloys have a strong tendency to produce pores, and they are also prone to oxidation and inclusions. Therefore, preventing and removing gas and oxidation inclusions has become the most prominent problem in the aluminum alloy melting process.

In order to obtain high-quality aluminum alloy liquid, its smelting process must be strictly controlled and measures must be taken to control it.

Aluminum Casting Filters can effectively block slag mechanically.

When the molten metal passes through the ceramic foam filter with complex structure, the filter medium filters out the inclusions larger than the pore size of the filter surface through mechanical separation, and makes them precipitate on the flowing end of the liquid metal of the filter.

As the number of inclusions on the surface of the filter increases, a layer of “filter cake” will gradually form, which will further narrow the flow channel of the molten metal. Therefore, the surface of the new filter medium can filter out finer inclusions.

At the same time, the inside of the medium also has a filtering effect. Among the many small holes that penetrate the ceramic body, some show tiny slits, and some have dead corners. These different areas of change are possible positions for intercepting inclusions. Inside the filter There is also a “filter cake” effect.

Adtech’s recommendations for the use of Aluminum Casting Filter

1. According to the melting point of the alloy, select the filter of the appropriate material to avoid excessive temperature, damage the function of the filter and fail to achieve the filtering effect.

2. Select the corresponding mesh, and the purification effect should match the casting requirements.

3. Try to use the upper limit of T. Art for the casting temperature to increase the fluidity of the metal.

4. When the filter is placed horizontally under the mouth cup or parting surface, the casting height should not exceed 20cm. It is best to flush the metal liquid on the mouth cup wall, not directly to the filter.

5. The filter must be handled gently. When not in use, place it in a dry and ventilated place to avoid moisture absorption affecting the strength of the filter.