Aluminium Siberia Ceramic Foam Filter Supplier

Aluminium Siberia, a mighty aluminium producer, the second-largest in the world, has risen from the wilds of Siberia – and the big European banks don’t know what to do with it.

Russian Aluminium has an annual turnover of more than $5 billion, produces one in every 10 tonnes of the world’s primary aluminium, and the commodities finance specialists say they can’t afford not to lend to it. But credit committees caution that its general director and others face a $2.7 million damages civil action in a New York court alleging ‘numerous criminal acts, including murder, extortion, mail and wire fraud and money laundering’.

Aluminium Siberia Ceramic Foam Filter Supplier Adtech keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

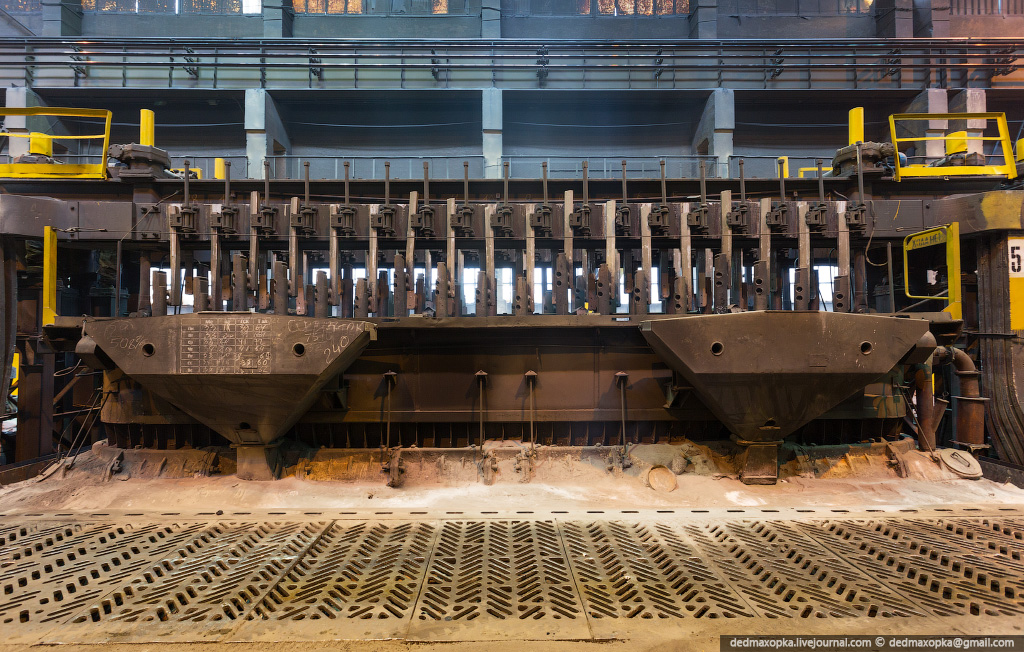

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

Aluminium Siberia uses Ceramic Foam Filter which is suitable for the production of high quality and high requirements aluminum sheet and foil. Through physical adsorption and chemical action, it can effectively remove various oxidation inclusions generated during aluminum smelting process, thereby reducing casting defects and improving casting quality. Deep processing provides quality materials.

The quality of the melt Aluminium Siberia is important, which greatly affects the subsequent processing properties and the quality of the final product. Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for Siberia Aluminium pollution. On the one hand, during the melting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag. (such as furnace lining debris, chlorides, carbides, etc. in the flux) as well as coarse intermetallic particles and the like.

On the other hand, part of the waste material in the composition charge carries some non-aluminum impurities during the circulation. Since the waste comes from the process waste and waste of the various processes of the factory and the waste outside the factory, the route is different, the composition is complex, and the quality is also poor.

These impurities tend to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing properties, mechanical properties, corrosion resistance and appearance quality of the product.

Aluminium Siberia Ceramic Foam Filter Supplier Adtech can effectively remove all kinds of fineness in the aluminum water to the micron-sized inclusions, making the aluminum water into a smooth laminar flow, which is conducive to filling.

It has good mechanical strength and chemical stability, superior aluminum washability; tightly controlled hole size and through-hole ratio for stable filtration.

The filter plate is surrounded by a sealed heat-expandable ceramic fiber gasket, which helps the filter plate to seal in the filter box, ensuring no metal liquid bypass.