Aluminium Scrap Liquid Metal Filler For Aluminium plays a very important role in improving the quality of castings.

Slag inclusions in aluminum alloy castings are one of the main factors affecting the quality of deep-processed products. The quality of the product directly affects its market share and economic benefits. In order to survive and develop, it is necessary to increase the added value of products and carry out deep processing.

It can effectively filter liquid-solid non-metallic inclusions in molten metal once or twice, thereby reducing slag holes, improving the mechanical properties of castings, reducing machining allowances, improving surface finish, and prolonging the service life of castings.

At present, various complex castings such as cylinder blocks and cylinder heads produced by foundry companies require aluminum foam ceramic filters, and the annual consumption can reach tens of millions of pieces.

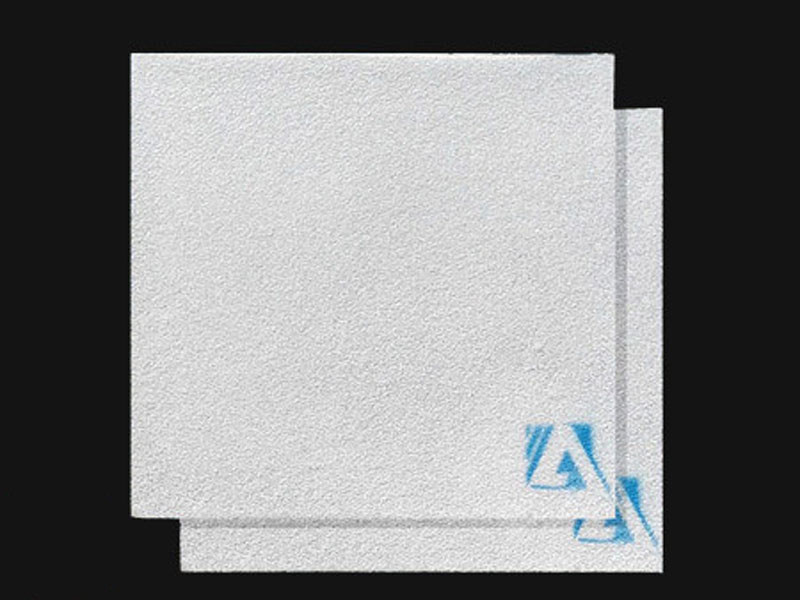

AdTech has a complete quality control system for ceramic foam filters, including technical standards, testing equipment and testing methods to achieve product quality control requirements.

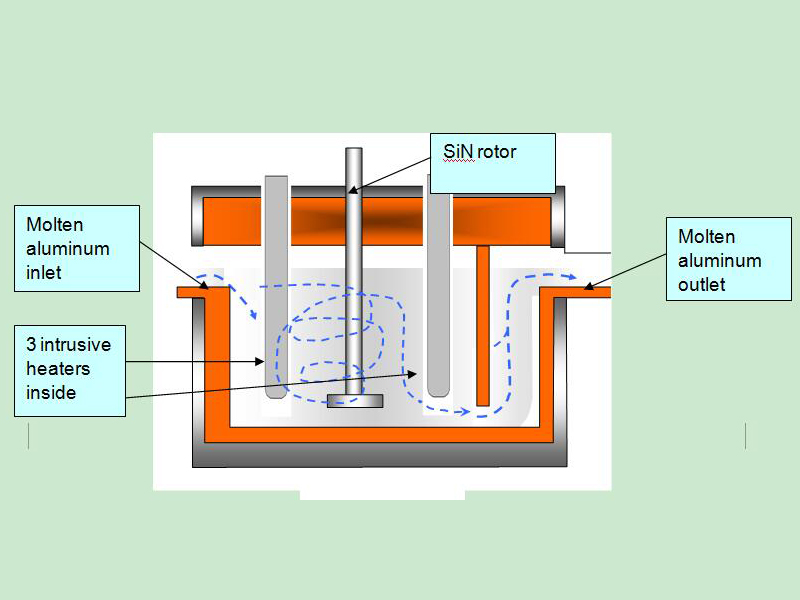

Molten aluminum foam ceramic filter plate is a new type of filter plate made of industrial sponge as a carrier, filled with heat-resistant ceramics, and then sintered.

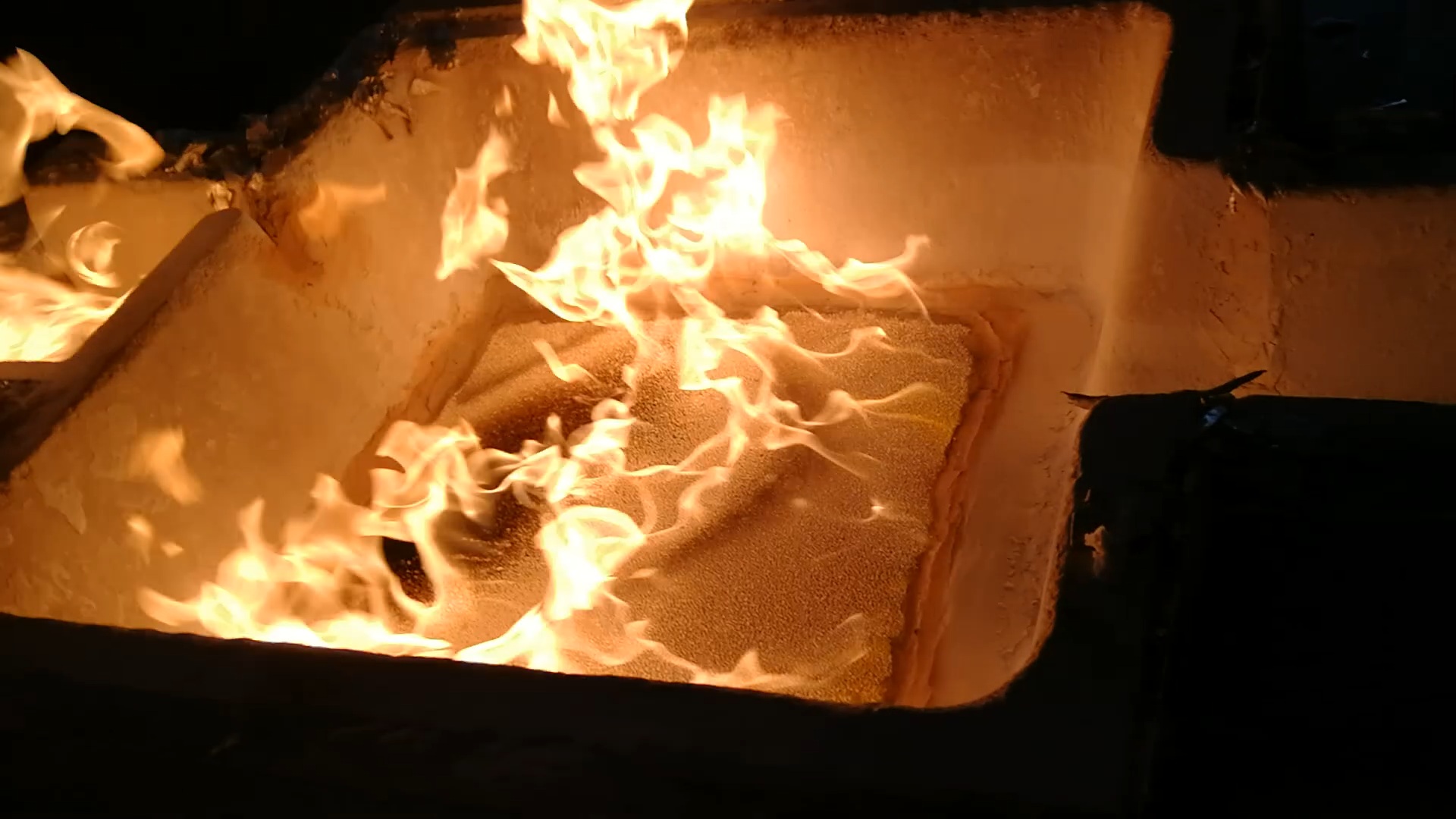

When the ceramic filter plate filters the molten aluminum, the molten aluminum flows through the tortuous holes of the ceramic filter plate, and the non-metallic impurities and oxide film (commonly known as slag) in the molten aluminum.

Due to the combined action of the axial pressure, friction and surface adsorption of the molten aluminum, it is retained on the inner surface of the ceramic filter plate and the gap cavity, thereby separating the slag and the molten aluminum.

Cast aluminum and aluminum alloys are aluminum castings produced by casting methods. Deformed aluminum and aluminum alloys are processed products produced by pressure processing methods.

The quality of aluminum ingot raw materials directly affects the quality and production efficiency of aluminum alloy die castings.

Good raw materials can reduce mold wear, extend mold life, reduce costs, and improve production efficiency.

Since 2012, AdTech has focused on the R&D, production and sales of Aluminium Scrap Liquid Metal Filler For Aluminium (CFF) for aluminum alloy casting.

AdTech’s molten aluminum foam ceramic filter plate technology has been widely accepted by the market and is applied to many series of aluminum alloy products: high-precision filtration and purification of cast aluminum alloys, such as aluminum foil wool materials, PS board bases for printing, canned materials, elastic packaging materials, Rail transit, aerospace products, cables, wires, etc.

After the aluminum alloy material is mixed with slag, the performance of the alloy deep-processed parts will be destroyed, and the yield will be reduced, which will cause a certain economic loss. In production, the method of slag removal and filtration is required to eliminate slag inclusions as much as possible.