Aluminium Porous Filter Material

Aluminum alloys are characterized by their low specific weight, low melting point, negligible gas solubility with the exception of hydrogen, excellent castability, good machinability, and good corrosion resistance. Premium quality castings are an essential requisite for the critical structural components used in automotive and aeronautics. The production of such castings requires that inclusions and porosity be minimized (or even eliminated) to supress their harmful influence on the mechanical properties, so that these properties are then mainly controlled by the microstructure of the castings.

The presence of hard non-metallic inclusions in aluminum alloys can not only degrade the mechanical properties of the final product but also create a number of other processing-related problems in diecasting which include the following:

Reduction in mechanical properties of the casting

Both tensile strength and elongation are reduced drastically with the increase in inclusion content. Clean metal, in general, is characterized by high tensile properties (yield strength, ultimate tensile strength, percent elongation).

Poor machinability and high tool wear

Some of the inclusions that may often be present in the casting are brittle and extremely hard ceramic particles. The hardness of some inclusions can be measured on Mohs scale as compared to 10 for diamond. When an alloy melt is cleaned by filtration before casting, machinability improves quite significantly.

Loss of fluidity and feeding properties

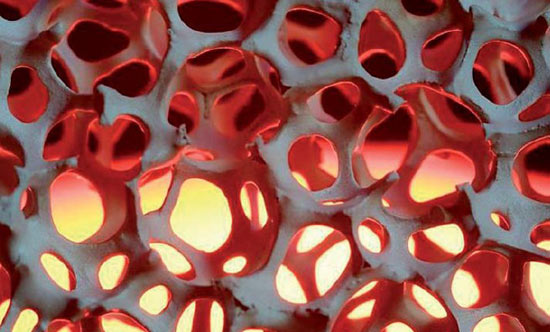

Inclusions in molten metal produce a decrease in fluidity. Producing clean molten metal through filtration can increase the fluidity substantially, by as much as 30% at normal operating temperatures.

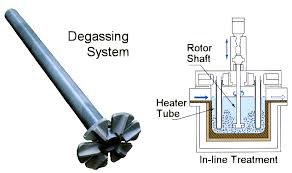

Increased gas porosity

The dissolved hydrogen level in aluminum alloy melts is the main factor responsible for gas porosity formation during solidification. The solubility limit of hydrogen in molten aluminum is significant, but reduces considerably when the metal is solidified, leading to gas porosity formation. The gas porosity after solidification depends not only on the hydrogen content in the molten metal, but also on metal cleanliness. Oxides act as pore nucleation sites and hydrides decompose upon cooling to produce dissolved hydrogen.

Poor surface quality and lack of pressure tightness

Defects in aluminum products such as pinholes in thin foils and razor streaks in lithographic plates are commonly caused by inclusions. Inclusions, in size range of 10 – 20 μm effective diameter can, at a concentration of a few parts per million, be harmful in rolled aluminum products.