Aluminium Liquid Degasser

Aluminium Liquid Degasser is based on the principle that dissolved hydrogen gas will move from an area of high concentration (in the melt) to an area of low concentration (in the inert gas).

Hydrogen gas disperses in molten metal as it would if it were released in any confined space.

It will maintain a constant concentration throughout the melt.

Hydrogen gas can migrate in liquid metal almost as fast as it can in air.

Sources of hydrogen in molten aluminum:

atmosphere humidity

wet metallic charge

wet furnace lining (crucible, transfer ladles)

wet foundry instruments

wet fluxes and other consumables

furnace fuel combustion products containing hydrogen

Therefore, it is unnecessary to bring every ounce of metal in contact with the inert gas. The efficiency of aluminum degassing is

determined by two factors, the transfer rate across the metal/gas interface and the total surface area available for transfer.

Aluminium Liquid Degasser Product Feature

1. Based on product quality and process requirements, body structure has overall lining and assembly lining.

2. Filtering form has horizontal type and plug-in type.

3. Filtering pass has single-stage, two-stage and three-stage.

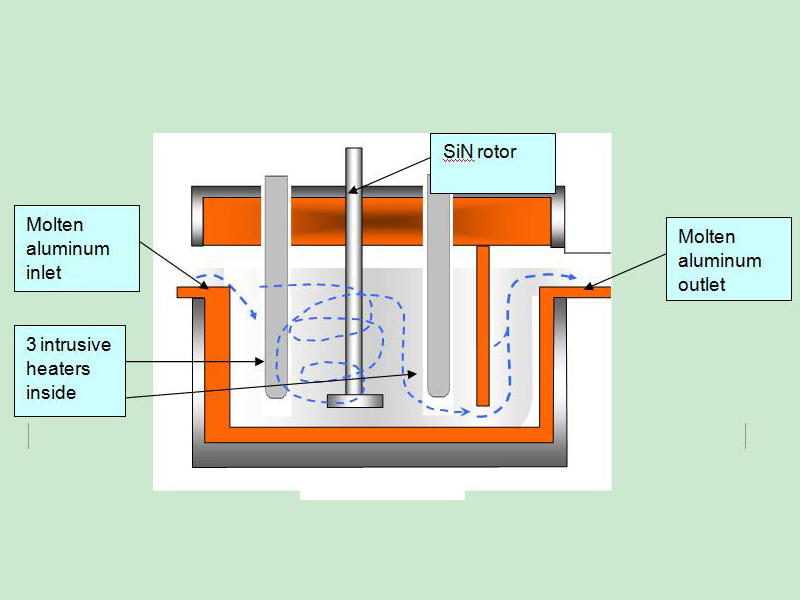

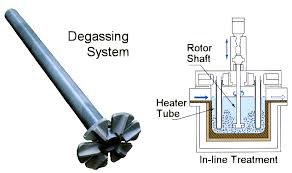

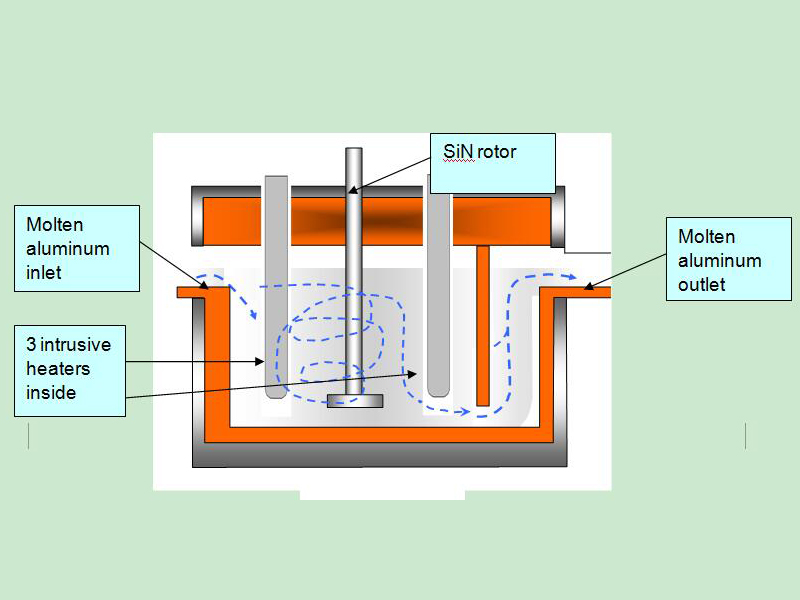

In the rotary Aluminium Liquid Degasser method an inert or chemically inactive gas (Argon, Nitrogen) is purged through a rotating shaft and rotor.

Energy of the rotating shaft causes formation of a large number of fine bubbles providing very high surface area-to volume ratio.

Large surface area promotes fast and effective diffusion of hydrogen into the gas bubbles resulting in equalizing activity of hydrogen in

liquid and gaseous phases.

Aluminium Liquid Degasser allows achieve more complete hydrogen removal as compared to the flux degassing.

Additionally rotary degasser does not use harmful chlorine and fluorine containing salts.

Aluminium Liquid Degasser may also combine the functions of degassing and flux introduction.

In this case the inert gas serves as carrier for granulated flux. The method is called flux