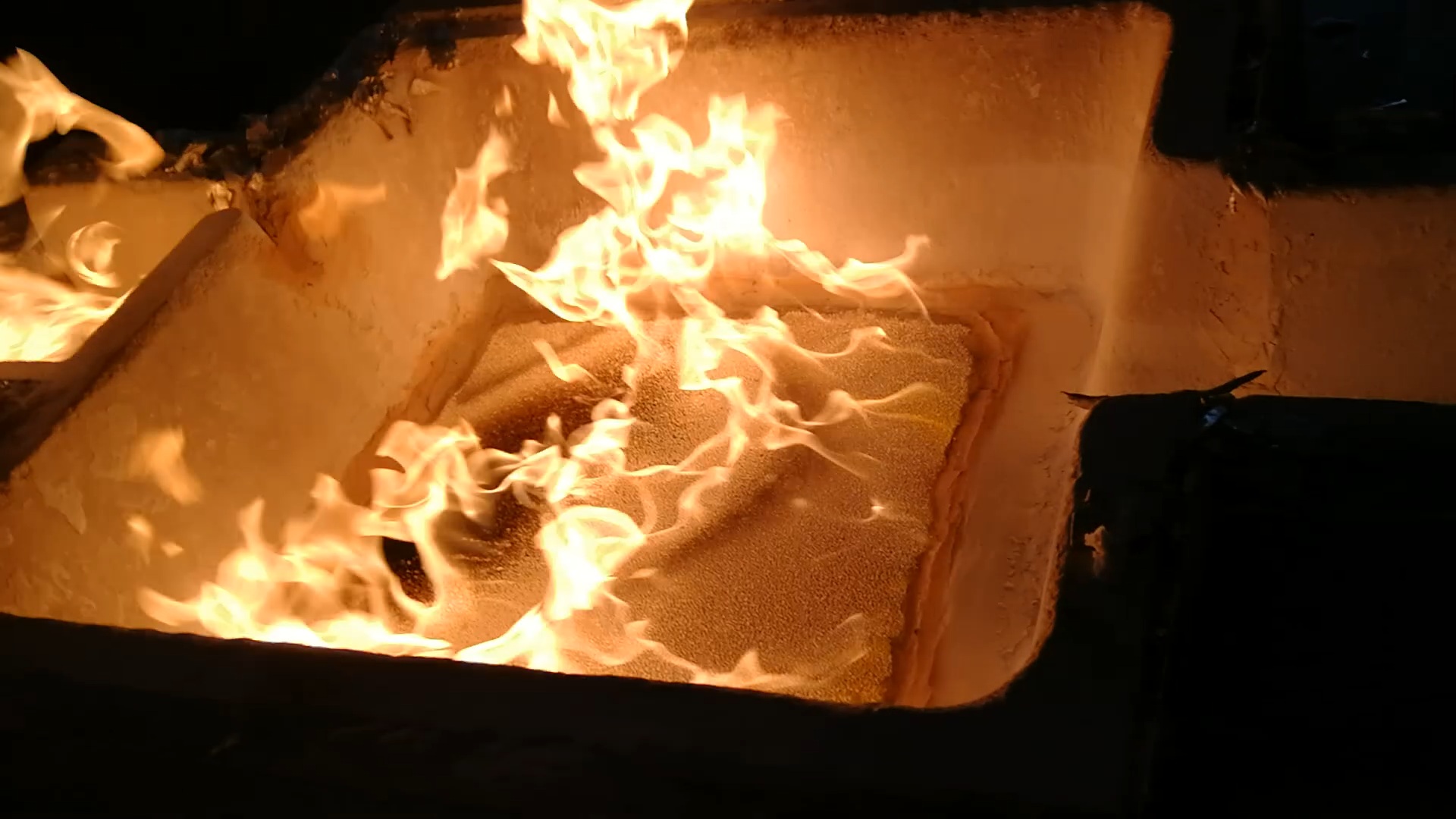

Aluminium Foil Ceramic Foam Filter is a new type of ceramic foam filter molten metal filter developed in recent years, which can reduce casting defects. It plays a vital role in the ceramic filter of the casting and foundry industry. It is used to filter molten metal.的impurities. Improve the quality and performance of the final product.

Even the finest non-metallic impurities in the molten metal can have a destructive effect on the performance and strength of the finished metal. This may cause the final product to fail to meet the necessary quality standards; ceramic filters play a vital role in removing these impurities and ensuring high-quality castings.

Uses of Aluminium Foil Ceramic Foam Filter

Purify molten metal liquid

Simplify the gating system

Improve the metallurgical structure of castings

Reduce slag inclusion in castings

Improve casting qualification rate

Reduce internal reoxidation defects in castings

Reduce surface defects after casting

Advantages of Ceramic Foam Filter Aluminium Foil

High strength, no loose ceramic particles or powder

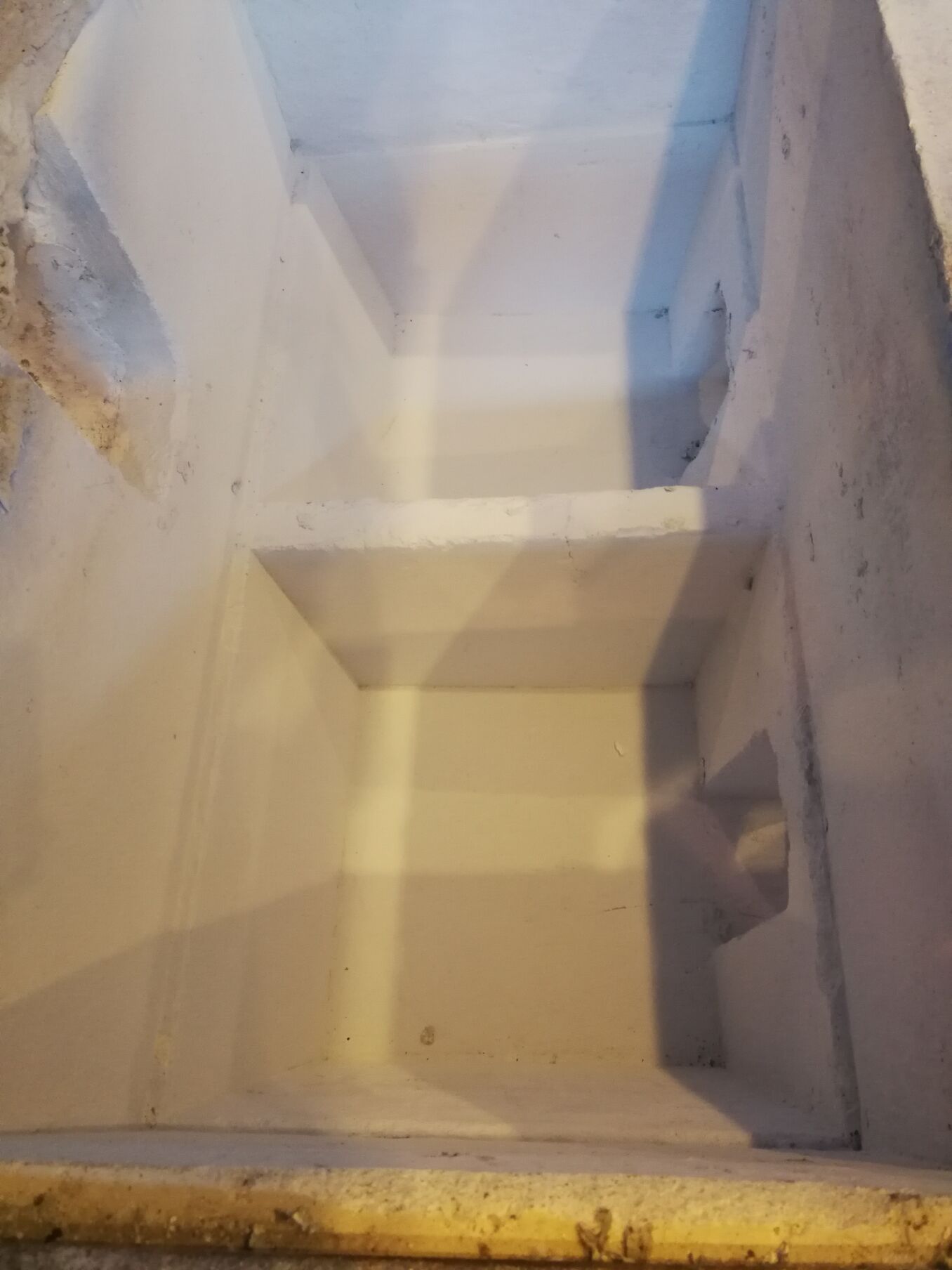

Three-dimensional connected mesh structure, high porosity

Large slag collection surface area, large filter internal surface area

Excellent thermal shock resistance

Available in various sizes, shapes and apertures

Particles larger than the pore size are captured on the top of the ceramic foam filter

The smaller particles are captured by the filter cake formed by the larger particles

Fine particles are trapped in the pores of the filter