Aluminium Filter Ceramic Foam

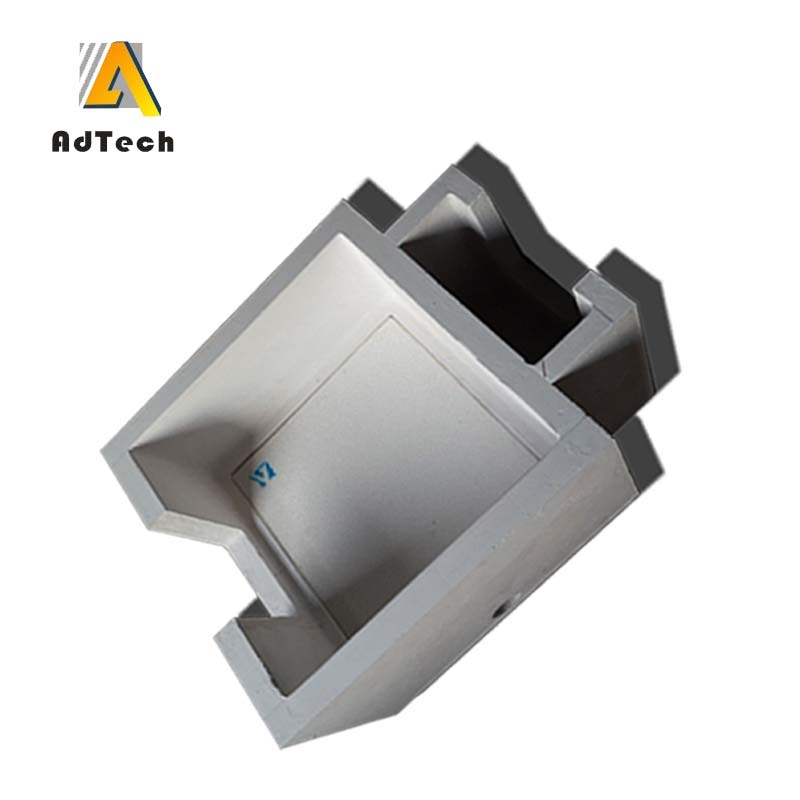

Aluminium Filter Ceramic Foam is a porous ceramic with high porosity (80%~90%) with three-dimensional grid structure.

Because of its low density, high strength, high temperature resistance, corrosion resistance and good filter adsorption.

Therefore, it is widely used in the fields of metal melt filtration, automobile exhaust gas treatment, medical materials, and the like.

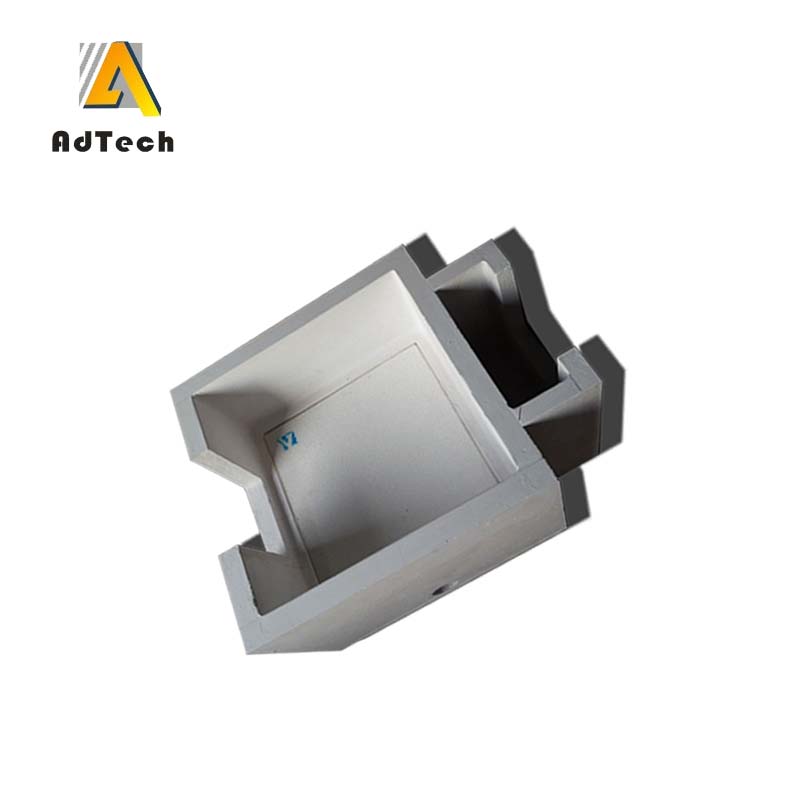

In recent years, through the development of the third-generation filter material, CFF (Ceramic Foam Filter), the qualified rate of finished products of metal smelting products has been greatly improved, and the performance of the products has been greatly improved.

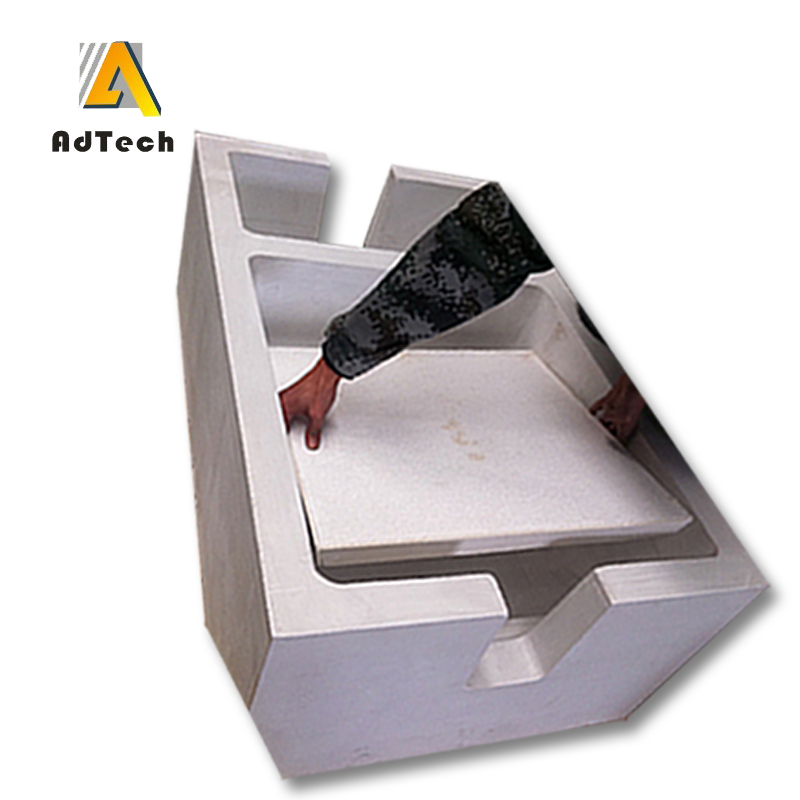

Casting is one of the most widely used industries for foam ceramic filters. Its function is to make the turbulent and tossed metal liquid pass through the foam ceramic honeycomb hole and become a smooth, uniform and clean metal liquid.

Thereby, the scrap rate of the casting due to casting defects such as non-metallic inclusions is greatly reduced, and the production cost is saved.

The shotcreting process is a process produced by Aluminium Filter Ceramic Foam.

Aluminium Filter Ceramic Foam production process

3. The foam ceramic filter board is made of polyurethane foam as a carrier and immersed in ceramic slurry made of ceramic powder, binder, sintering aid, suspending agent, etc.

Then, the excess slurry is squeezed out, and the ceramic slurry is uniformly applied to the carrier skeleton to form a green body; the green body is dried and sintered at a high temperature.

This kind of process, also known as organic foam impregnation method, is a common foam ceramic production process in China.