Aluminium Degass is subject to changes in the internal structure, size and position of the box, which have a great impact on the size, number and distribution of refined bubbles.

The degassing medium is recommended to use 99.996% nitrogen or high-purity argon that has been dehydrated and dried.

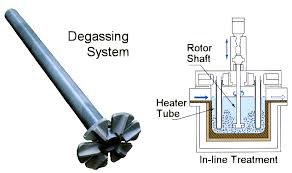

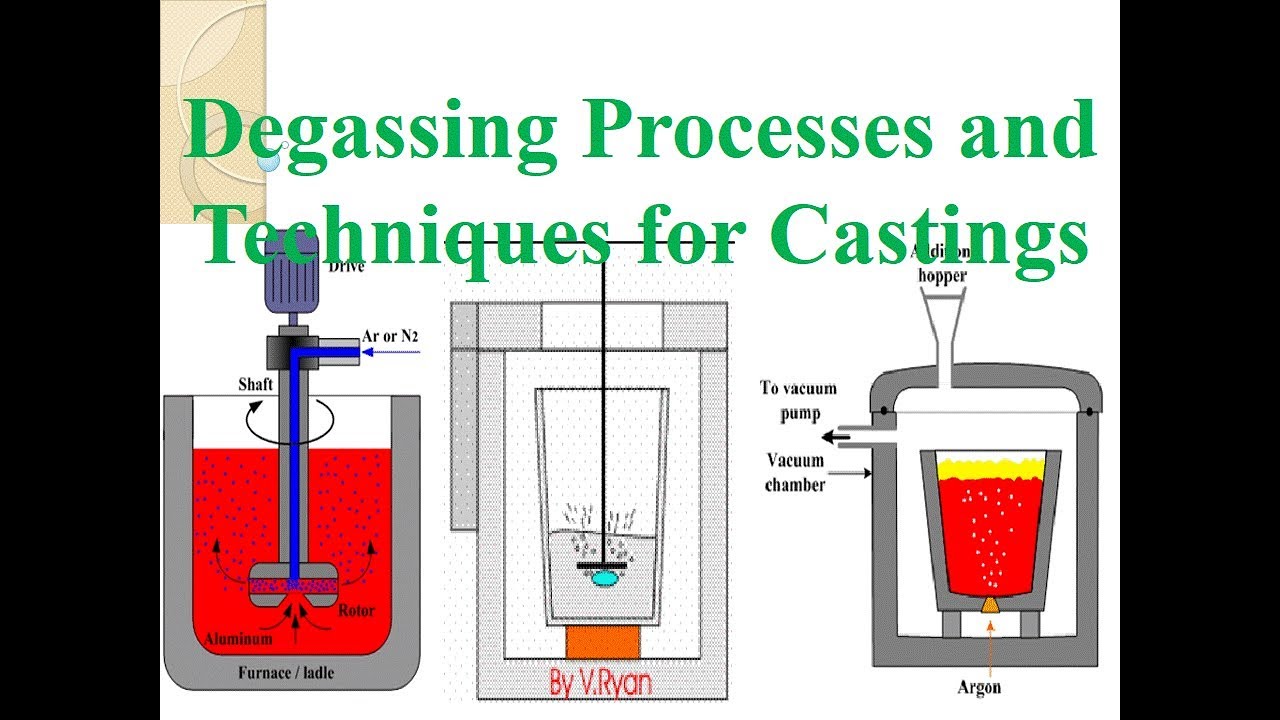

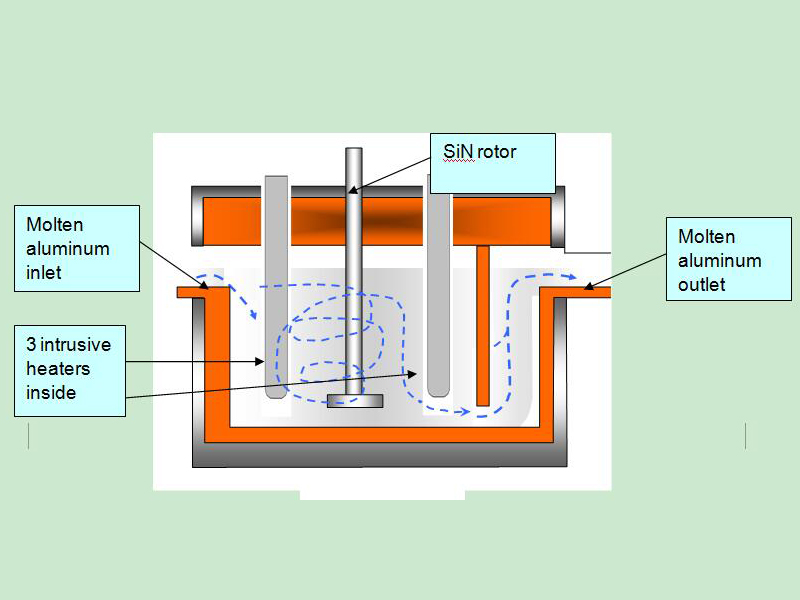

Aluminium Degass stirs the aluminum liquid through a controlled rotating silicon nitride rotor, and at the same time presses a metered inert gas into the aluminum liquid through the rotor and breaks them into tiny bubbles, so that they are evenly dispersed in the molten metal. The gas content of the bubbles The pressure is zero.

Due to the high partial pressure of hydrogen in the molten aluminum, the hydrogen in the molten aluminum continuously diffuses into the bubbles, and at the same time, some non-metallic inclusions in the molten aluminum are adsorbed on the surface of the bubbles, and the useless hydrogen and some non-metallic inclusions are inert. The gas bubbles float up to the liquid surface.

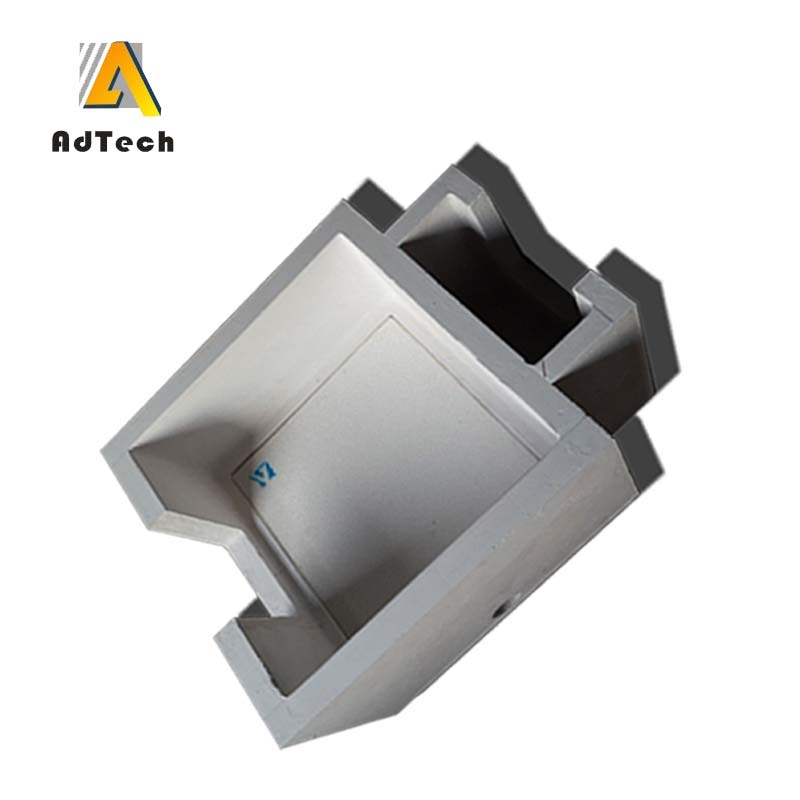

When there is a special degassing filter box, these slags are isolated before pouring, and then the slag skimmer is used to remove hydrogen and remove oxidized inclusions.

The principle of degassing is also recognized. It has high efficiency and good effect without affecting the production process. It can improve the purity of molten aluminum in a short time, reduce the scrap rate, increase production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products. , This is what the traditional degassing method cannot achieve.

The main frame of the Aluminium Degass Unit is mainly based on electric welding. The frame and the pillar, the electrical cabinet frame, the lifting chain suspension, the machine head and the movable position of the machine head are all welded. Then sand and polish.

The head sealing plate, the electrical cabinet sealing plate, the moving position of the machine head and the machine head are mainly fixed by bolts, and all kinds of motors and switches are also fixed by bolts.

The lifting mechanism of Aluminium Degass Unit adopts two ways of hydraulic rail drive or motor gear drive, and it can also be made into a hoisting type.

Surface treatment of Aluminium Degass Unit

After removing rust on the surface of the main body of the rack and the electrical cabinet frame, do anti-rust treatment and then do two painting treatments.

The machine head sealing plate and the electrical cabinet sealing plate adopt rust removal and plastic spray treatment after degreasing.