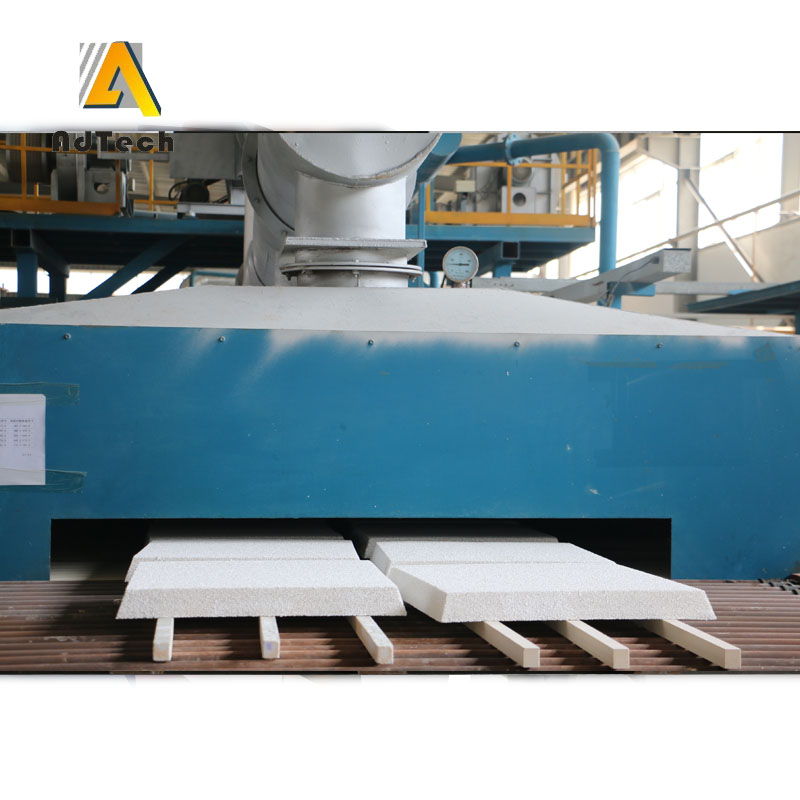

Aluminium Casting Honeycomb Ceramic Filter Parameter

Honeycomb Ceramic Filter Parameter during aluminum and aluminum alloy production

178×178×50mm, 230×230×50mm, 305×305×50mm, 381×381×50mm, 432×432×50mm, 508×508×50mm, 584×584×50mm, a total of seven major specifications of foam ceramics Filter plate products. Other specifications and models are required. Both supply and demand can be negotiated by both parties.

Honeycomb Ceramic Filter Parameter Folding Dimensions and Shape Deviation

For the size and shape deviation of the foam ceramic filter plate, we mainly consider the side length tolerance which has a great influence on the use of the foam ceramic filter plate. Diagonal length tolerance The plane gap thickness tolerance The deviation of the inclination angle is 5 indicators.

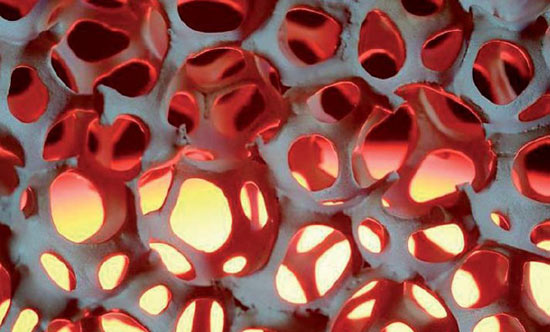

Honeycomb Ceramic Filter Folding Light Transmittance

Transmittance refers to the effective filtration area of Honeycomb Ceramic Filter products. The higher the light transmittance, the less blind holes are, and the more effective the filter holes (potholes), the better the filtering effect.

The foam ceramic filter plate to be inspected is placed on a light box with a built-in 200W incandescent bulb, and a square transparent plastic plate with a uniform 5.0×5.0 mm square is used to measure the light transmissive area of the large surface of the filter plate, thereby calculating the test. The light transmittance of the filter plate is used to determine the light transmittance of the filter plate. In this standard, the light transmittance (through hole ratio) of the filter plate is specified to be 95% or more.

Honeycomb Ceramic Filter Folding Porosity

Porosity is the percentage of the total volume of the cavities in the filter plate product to the total volume of the filter plate product. The porosity determines the filtration capacity of the foam ceramic filter plate per unit volume. The larger the porosity, the larger the filtration flow rate of the filter plate and the stronger the filtration capacity, and vice versa.

Honeycomb Ceramic Filter Folding Compressive Strength

In the process of transportation and use of the filter plate, the filter plate must withstand the impact of a certain pressure from the outside, so the index of compressive strength is also introduced in the standard as one of the basis for measuring the quality of the filter plate.

The higher the compressive strength, the more durable the product, the better the quality, and vice versa.

Honeycomb Ceramic Filter folding thermal shock resistance

Thermal shock resistance refers to the resistance of foam ceramic filter plates to damage caused by rapid temperature changes. In the use of foam ceramic filter plates.

Filtration should begin before the filter plate is gradually preheated to the temperature of the filtered aluminum melt.

This requires the filter plate to have a certain thermal shock resistance. The better the thermal shock resistance, the more durable the filter plate and the better the quality.