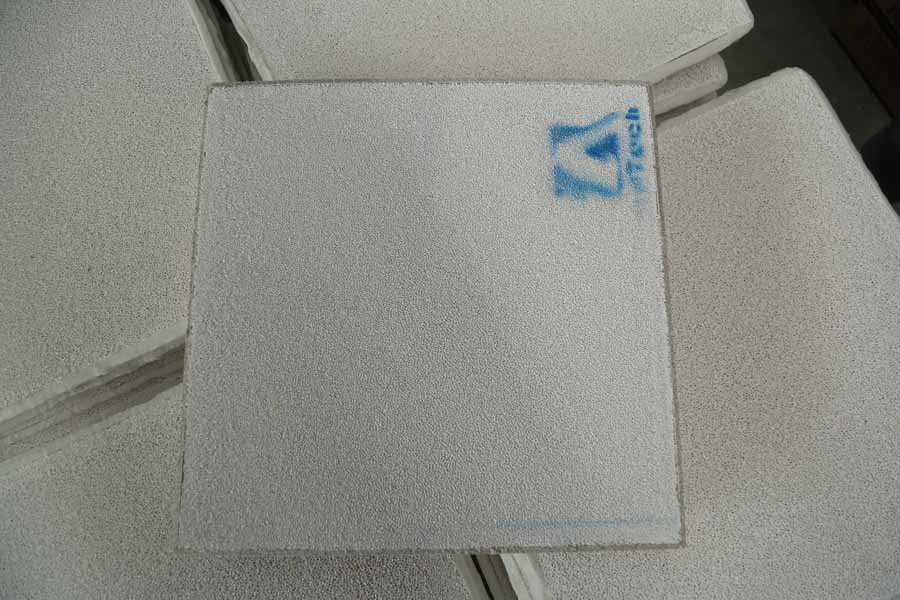

Aluminium Alloy Ceramic Foam Filters For Casting has the characteristics of high temperature resistance, corrosion resistance, molten metal erosion resistance, high strength, high qualification rate, and large surface area. It is mainly used in the filtration and purification of metallurgy and casting metal liquids.

The molten metal mixture flows through the porous structure of the ceramic foam to become uniform, smooth, and clean molten metal.

It removes micron-level inclusions, and some wrapping gas reduces the erosion of the sand mold and reduces the product obsolescence rate.

Ceramic foam filters can be made with different pore sizes and porosities to obtain satisfactory filtering effects.

Advantages of Aluminium Alloy Ceramic Foam Filters For Casting

–Compact, short and direct gate system

–Laminar metal

-The available template area is larger

-Due to high filtration efficiency, non-metallic inclusions are significantly reduced

-Improved the technical performance of castings

-Increase production

Features of Aluminium Alloy Ceramic Foam Filters For Casting

1. High permeability, good strength and thermal shock resistance, stable quality, and no matter whether it is a large size or small ppi product, it will not lose impurities at high temperatures.

2. Advantages compared with traditional filter materials: thermal and chemical stability at high temperatures-avoiding chemical reactions with filtered molten metal.

3. Pure ceramic composite material has high porosity and good mechanical strength at high temperature.

4. Fully open holes, ceramic particles or powder will not be lost during the filtration process (snowing).

5. Easy to operate and energy saving. Make the metal flow smoothly, avoid sputtering and reflow, thereby improving the surface quality of the casting, preventing hole deformation, and ultimately reducing the rejection rate.

[…] of high-purity cast metal. Reduce the scrap rate of finished products and improve product quality. Ceramic cast filters are usually standard size (inches) with a porosity of 10-60 PPI (pores per inch). The size of the […]