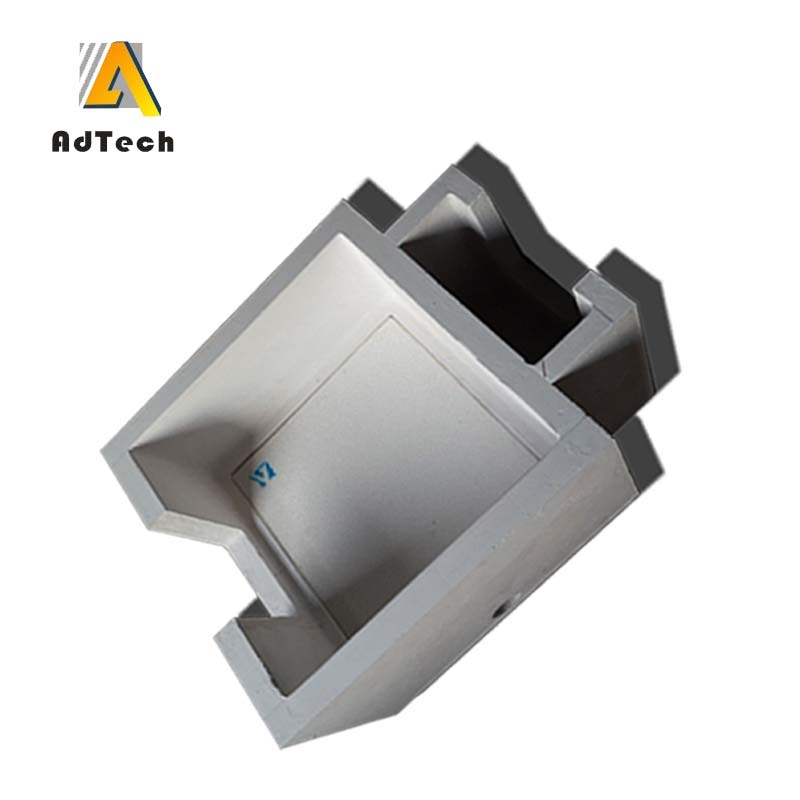

Aluminium Alloy Ceramic Foam Filter is made of structured foam sponge and high-purity ceramic material. Its interior is filled with intersecting and penetrating micropores, which can effectively intercept and absorb the tiny impurities in molten aluminum, which will help solve the problem of casting Slag inclusion problem in aluminum.

Features of Aluminium Alloy Ceramic Foam Filter

Fully automatic production line produced by 120m roller kiln

High strength, no slag, good thermal shock resistance;

High porosity, low filtration resistance, high surface energy, multi-phase adsorption capacity, no pollution to molten aluminum

Good stability when molten aluminum passes

Various specifications, available from 7 inches to 26 inches, can also be customized according to 20PPI to 70PPI;

Three different types of gaskets: fiber paper, fiber cotton and expandable

Ceramic Foam Filter Benefit

When electric heating, use more than 4-5 times of other CFF

The compressive strength of 1.26Mpa is 0.6-1MPa higher than other CFF

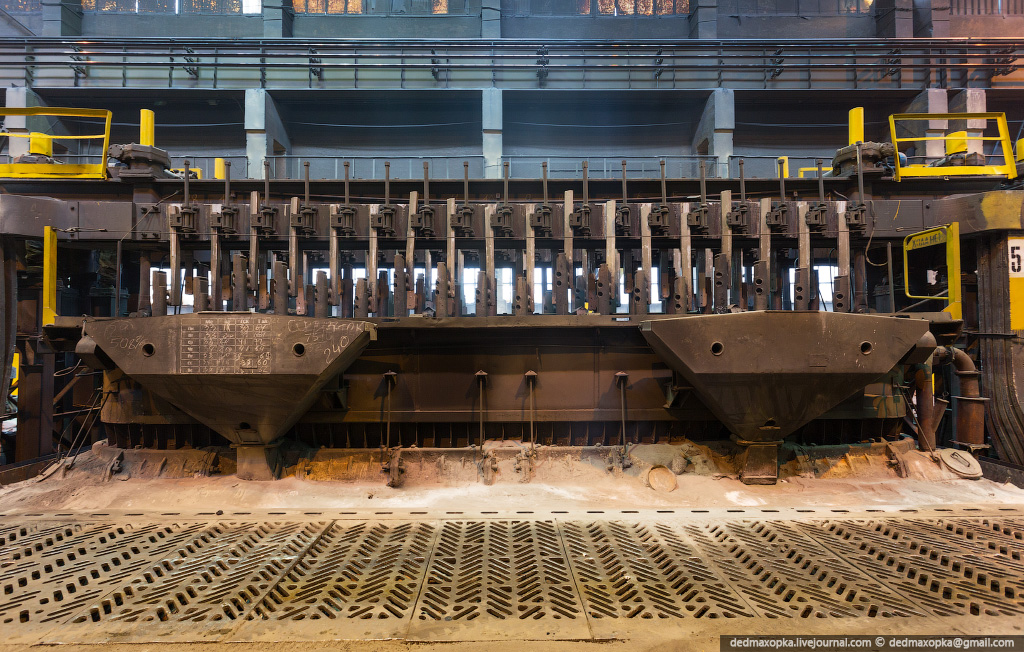

Ceramic Foam Filter Usage

Clean the filter box before using the filter

Gently place the CFF into the slot of the filter box and press the seal around to prevent side flow.

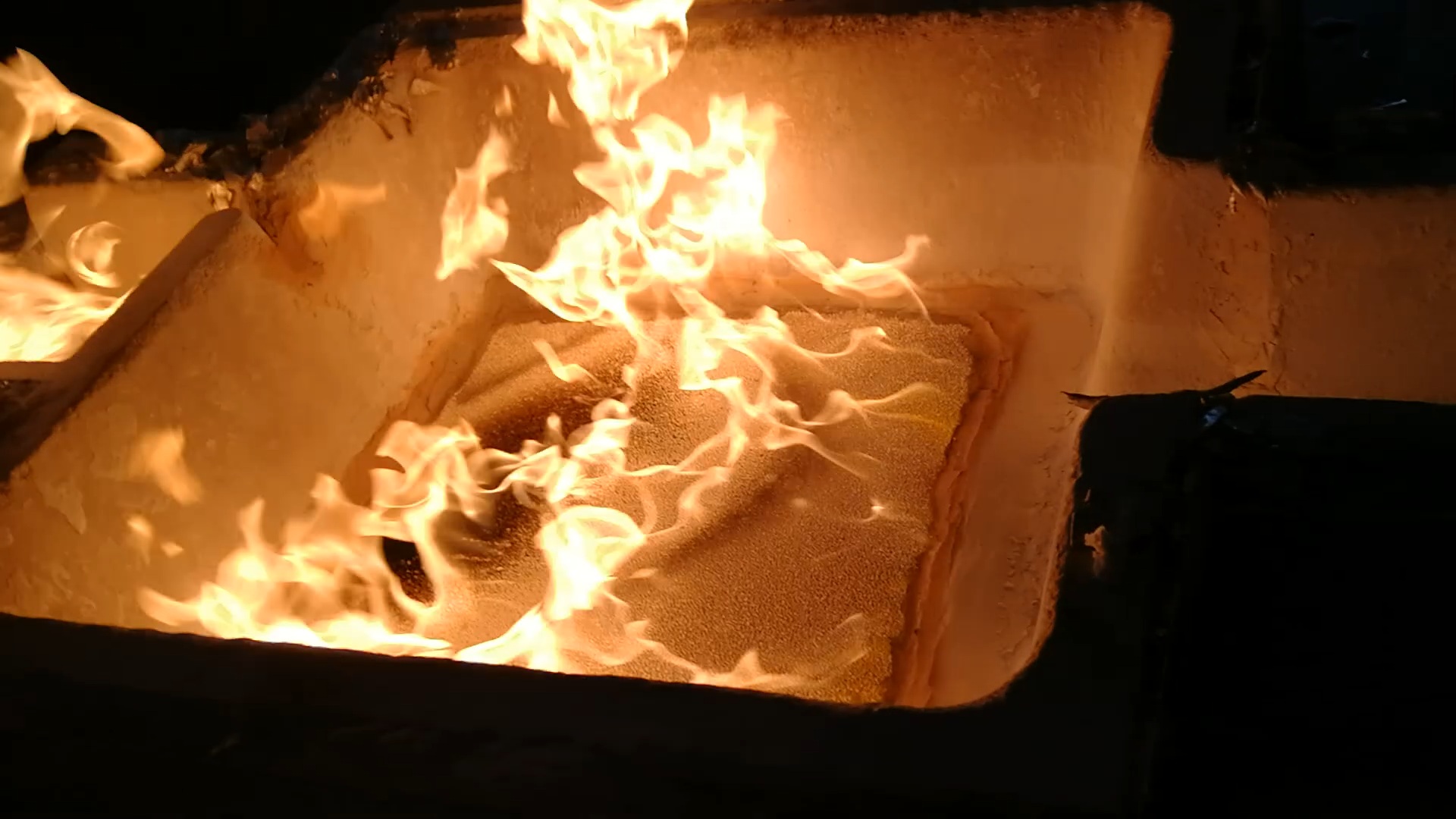

Preheat the filter box and CFF uniformly to make it close to the temperature of molten aluminum

Preheating with electricity or gas under normal conditions: 15-30min.

Fill the washing tank with molten aluminum during the filtration process to avoid impact and vibration

After filtering, take out the ceramic filter plate and clean the filter box in time.