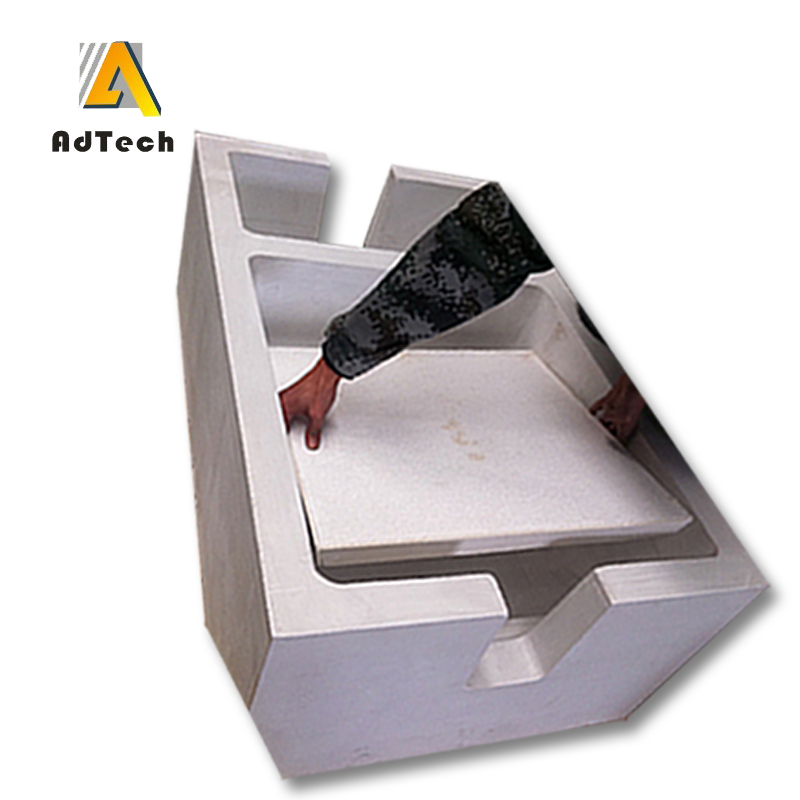

Aluminium Alloy Ceramic Filter For Foundry is inexpensive and stable in quality for European aluminum plants.

Swedish Aluminum said that China’s Aluminium Alloy Ceramic Filter For Foundry can provide a stable supply cycle.

Swedish Alcoa said that the ceramic foam filter is very important for the purification of aluminum melt.

The so-called purification treatment is to take various measures to reduce the unnecessary gas and solid matter in the aluminum melt to the allowable range to ensure that the performance of the material meets the standard or some special requirements.

To filter is to filter with a filter.

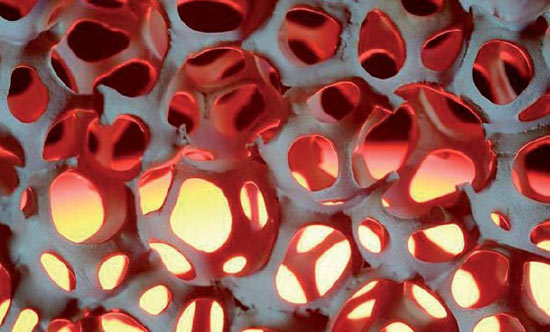

When the alloy solution flows through the filter with straight holes or with a three-dimensional mesh filter, the inclusions in the melt whose particle size is larger than the mesh size are filtered, and the framework with inclusions whose particle size is smaller than the mesh size is filtered. The inner surface of the channel is adsorbed.

When the alloy solution flows through the filter screen and the inner channel, the flow rate is reduced and divided into countless small liquid streams. These small liquid streams tend to flow laminar, thereby increasing the chance and speed of floating.

With the continuous accumulation and precipitation of the adsorbent, the screen size of the filter becomes smaller, and the particle size of the inclusions that can be adsorbed also becomes smaller, thereby improving the filtering effect.

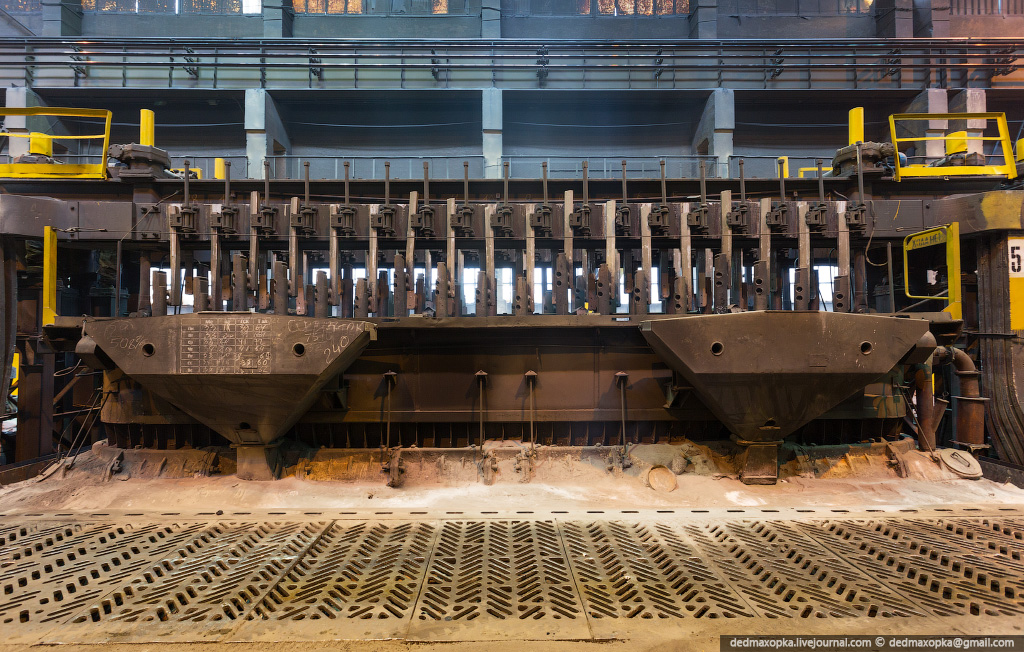

At present, the commonly used filters include glass fiber filters, ceramic plates, ceramic tubes, and foam ceramic filters.

Aluminium Alloy Ceramic Filter For Foundry is a commonly used filter tool in the aluminum and non-ferrous alloy smelting industry. Ceramic foam Filter For Foundry is white and made of high-purity alumina (Al2O3). This filter provides deep bed filtration to remove a large amount of impurities in the aluminum melt, and works at a dump temperature of up to 2000°F, while the mesh filter provides a thorough and deep filtration to remove molten aluminum or non- Impurities in aluminum. Black alloy flow. It has excellent resistance to high thermal shock, while maintaining effective removal of impurities through continuous and thorough filtration.