Aluminium Alloy Asian Foundry Filters are mainly used to filter aluminum and aluminum alloys in foundries and foundries. It is an effective aluminum fusion filter.

Its three-dimensional connected mesh structure, high porosity, has the advantages of large slag collecting surface area, large filtering internal surface area, small flow resistance, and good filtering effect.

Aluminium Alloy Asian Foundry Filters have the characteristics of light weight, high strength, large specific surface area, high porosity, excellent heat resistance and chemical resistance.

With the distributed mesh structure, they can increase the surface area and absorb thin waste, so the liquid metal can be formed safely.

Ceramic foam filter has excellent performance, can improve molding quality by reducing the rejection rate of molded products, and stand out from quality problems (such as waste holes, sand holes and pores).

Aluminium Alloy Asian Foundry Filters function

Purify molten metal

Simplified casting system

Improve the metallurgical structure of castings

Reduce impurities in castings

Improve casting quality rate

Reduce re-oxidation defects inside the casting

Reduce surface defects after casting

Ceramic foam filter Dimention

660x660x50(26″)

584x584x50(23″)

508x508x50(20″)

432x432x50(17″)

381x381x50(15″)

305x305x50(12″)

228x228x50(9″)

178x178x50(7″)

Ceramic foam fitler Pore Size (PPI): 10/20/30/40/50/60

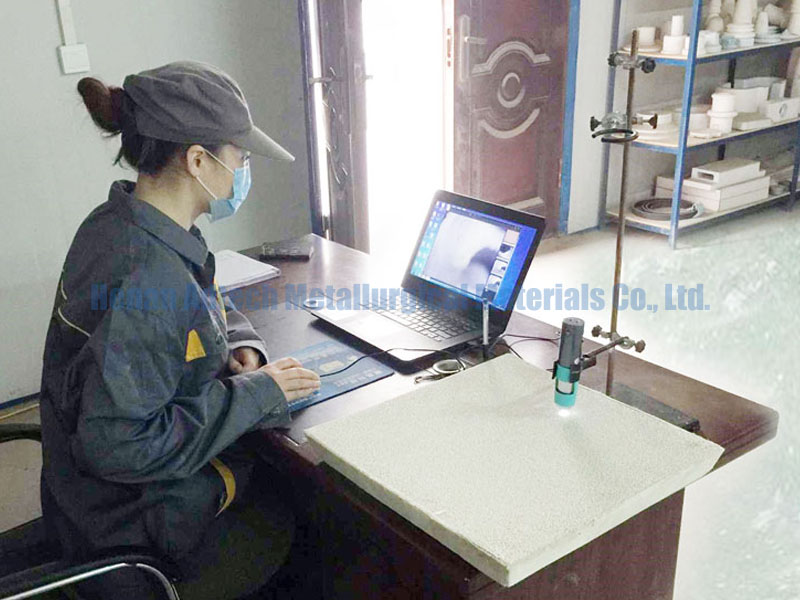

ADTECH keeps focusing on the manufacture of the metallurgical material.

ADTECH is one pioneer following by the International Enterprise, who keeps focusing on the manufacture of the metallurgical material.

1.Ceramic Foam Filter

2.Degassing Unit

3.Filter Box

4.Hot-top casting series

5.Roll casting nozzle

6.Flux series

7.Other Metallurgical Material

SALES@ADTECHAMM.COM