Alumina Porous Filter

What are the functions of Alumina Porous Filter?

Molten metal filtration

The amount, shape, size, type, and impurities and gases of inclusions in metals have a significant impact on their strength, plasticity, toughness, and the like.

The use of a porous ceramic filter to purify the molten metal can effectively purify the molten metal and improve the intrinsic quality and purity of the metal, which is simple and practical.

In addition to mechanical and reaction filtration, the mechanism of Alumina Porous Filter for purifying molten metal is more important to “rectify” the molten metal, so that the metal slag is destroyed, and the slag floating time is prolonged, thereby purifying.

The alumina ceramic filter is divided into a granular shape, a core shape, a mesh shape, a honeycomb shape, and a foam according to the structure.

Alumina Porous Filter has been widely used in the aluminum processing industry. There are two main modes in the application of deformed aluminum alloy melt purification technology.

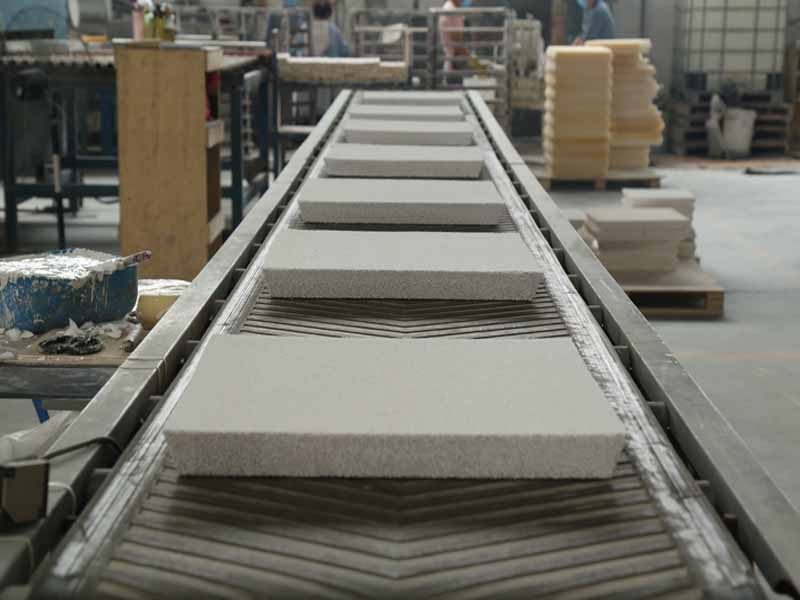

1. In-furnace fluxing and refining, semi-continuous casting of foamed ceramic plate filtration outside the furnace, ceramic filter plate replacement is one per casting, and some aluminum processing plants add a trough-type online deaerator before filtration to improve Purification effect.

The second type is adopted on the continuous casting line, and the replacement is based on the pressure difference before and after the filter plate to determine the replacement period.

How to choose Alumina Porous Filter

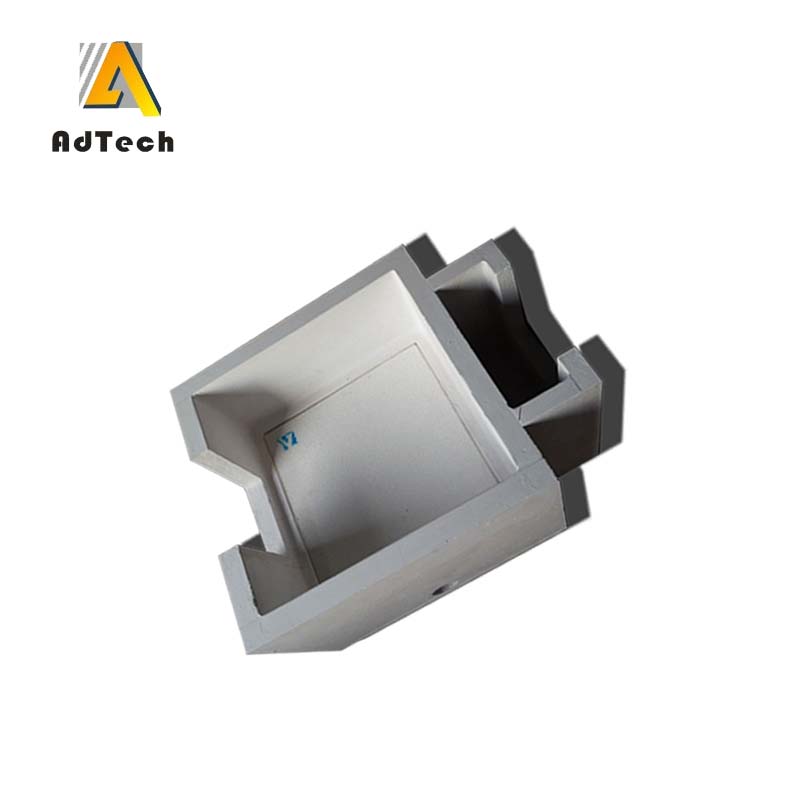

The Alumina Porous Filter specification is selected according to the unit time flow and total amount of liquid per unit time.

According to the cleanliness requirements of the final aluminum liquid, the Alumina Porous Filter is used. The higher the cleanliness requirement of the aluminum liquid, the smaller the selected pore size, which puts new demands on the structure and material of the foam ceramic filter.

With the development and application of various purification technologies of aluminum, Alumina Porous Filter purification is the last process of aluminum liquid purification. Before this process, it has used flux powder refining or online rotary degassing technology.

The particle of heterogeneous-hydrogen that has not been removed in the aluminum liquid is more fine and diffuse. How to promote the adsorption and separation of the heterogeneous phase is particularly important.

The “filter cake” effect of mechanical interception is not very prominent, so a new generation of foam ceramic filter materials that can promote heterogeneous agglomeration growth and hydrogen partial pressure suction has become the purpose and direction of this research.

Alumina Porous Filter filtration purification mechanism

1. By screening the habit collision interception and diffusion interception, mechanical filtration such as friction and sedimentation, the filtration efficiency is proportional to the mesh aperture of the foam ceramic. The smaller the mesh, the stronger the interception ability for small particles.

2, the deposition layer or filter cake layer effect, with the deposition of particles in the melt and the bending and bending of the interconnected and uneven grid support wall, the ability to capture the impurity particles is improved.

3. The rough surface formed by the surface gap of the mesh truss body increases the interface between the aluminum liquid flow and the ceramic solid surface, which can promote the disordered flow of particles in the aluminum liquid flow, which is beneficial to the solid particles being captured and deposited. .

4. Due to the microscopic cracks and pinholes on the surface of the mesh skeletal body, a fluoride flux with strong affinity for particles such as Al2O3 is pre-deposited, which promotes the complete cake layer effect and strong chemisorption force, and captures the ability of the retained heterogeneous particles. More strengthened.

5. From the melting process of the metal melt structure and the temperature field effect of the transmission process, the dense bottom difference of the alloy solute is inevitably formed, and the metal melt is redistributed—integrated—distributed—integrated, which is also a very Good alloying process.

Some high-melting metal phases and compounds re-aggregate and grow, and small heterophases aggregate and grow to facilitate filter capture.

This can also be explained by the change in the concentration of H, Al2O3, Fe, and Ti before and after filtration.

In particular, two-stage filtration or hole gradient thick plate filtration is more obvious.

Therefore, under the same premise, the new foam ceramic filter plate has high removal rate of miscellaneous phase of aluminum melt, and the change of static pressure difference before and after filtration is more change with time. The change of H content in aluminum melt before and after filtration is also obvious. Of course, the smaller the foamed ceramic pores, the better the cleanliness of the aluminum melt.