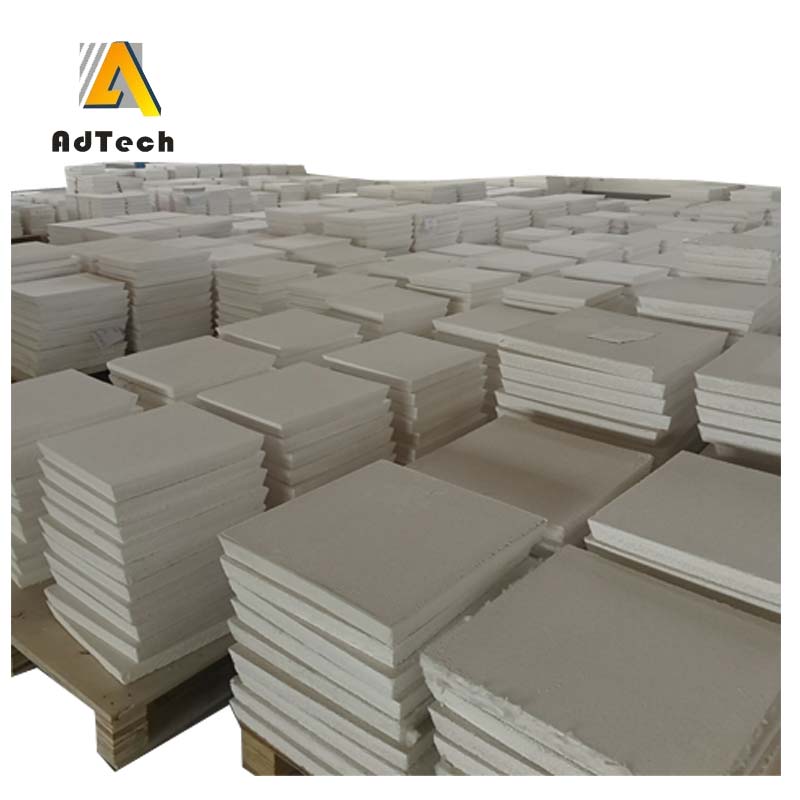

Alumina Polyurethane Foam Filter

The factors affecting the quenching temperature of the Alumina Polyurethane Foam Filter in the roller kiln were compared. The relationship between the height of the flame shield, the residual heat pressure, the size of the product and the quenching fan and the quenching temperature were compared in turn, and the reasons for the relationship were analyzed.

The product specifications are certain. Under the condition of not significantly increasing the energy consumption of firing, the quenching temperature is increased by reducing the height of the fire shield, increasing the residual heat pressure, and shutting down the quenching fan, which is beneficial to improving the mechanical strength of the foam ceramic product and reducing the slag. of.

Adtech also provide to the Ceramic Foam Filter Manufacturers In India, pls contact sales@adtechamm.com

The preparation process, classification and application fields of Alumina Polyurethane Foam Filter were analyzed for factors such as particle size, water content and shot size of alumina foamed ceramic filter plate spray slurry.

2. Compare the advantages and disadvantages of manual shotcreting and automatic shotcreting.

Study the advantages and disadvantages of spray blasting and spray drying after sizing and applicable conditions

A comprehensive analysis of the foam ceramic spray coating process

As a foam ceramic filter board manufacturer, the role of the spray coating process in the foam ceramic production process is further optimized.