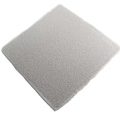

Alumina Foam Ceramics Foundry Filter

Alumina Foam Ceramics Foundry Filter is sintered by energy saving and environmentally friendly roller kiln.

Combined with the sintering characteristics of the foam ceramic filter plate, the specific parameters of the roller kiln were established.

For example, the ratio of the length of the pre-tropical zone of the roller kiln, the firing zone and the cooling zone, the selected sintering atmosphere, and the firing curve.

At the same time, the two different formulations and sintering methods of the ceramic filter plates compare the sintering temperature characteristics, the appearance quality and the physical and chemical properties of the sintered products.

Roller kiln has wide applicability to ceramic filter plates. Roller kiln sintered foam ceramic filter plates not only have stable product quality, small unit energy consumption, large output, but also have great practical value in waste gas recovery and waste heat utilization.