Alumina Filter

The quality of the aluminum melt is important, which greatly affects the subsequent processing properties and the quality of the final product.

Therefore, all countries in the world attach great importance to the purification of aluminum melt.

There are many reasons for aluminum pollution. On the one hand, during the melting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation, easily reacts with water vapor to absorb hydrogen, and easily forms various forms of non-metallic slag. (such as furnace lining debris, chlorides, carbides, etc. in the flux) as well as coarse intermetallic particles and the like.

On the other hand, part of the waste material in the composition charge carries some non-aluminum impurities during the circulation. Since the waste comes from the process waste and waste of the various processes of the factory and the waste outside the factory, the route is different, the composition is complex, and the quality is also poor.

These impurities tend to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing properties, mechanical properties, corrosion resistance and appearance quality of the product.

Introduction of Alumina Filter

1. It can effectively eliminate large inclusions in aluminum liquid.

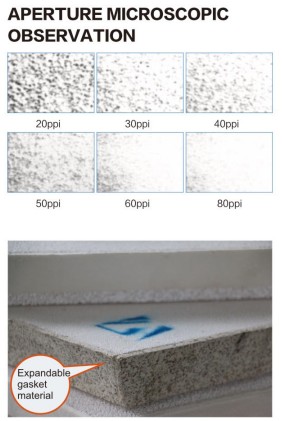

2. It can remove fine inclusions of several micrometers size which are incapable of conventional processes in aluminum liquid. At the same time, since the fine inclusions are filtered out, the effective number of crystal nuclei in the aluminum liquid is reduced, so that the aluminum liquid grows under large supercooling conditions, the solidification time is shortened, and the microstructure is refined.

3. Reduce the hydrogen content in the aluminum liquid. The hydrogen atoms can be adsorbed on some of the oxidized inclusions, and the oxidized inclusions can become the core of the bubble growth, so that the impurities are removed while filtering off the inclusions.

4. By adsorption, the content of harmful elements in the aluminum liquid can be removed.

Alumina Filter usage

1. Clean the filter box.

2. Gently place the Alumina Filter into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Evenly preheat the filter box and Alumina Filter to bring it close to the temperature of the cast aluminum solution.

4. Pay attention to the change of the aluminum hydraulic head during casting. The normal starting pressure head is 75-150mm. When the aluminum liquid begins to pass, the pressure head will drop below 25mm. Then the indenter will slowly increase.

5. After the filtration is finished, remove the Alumina Filter and clean the filter box.