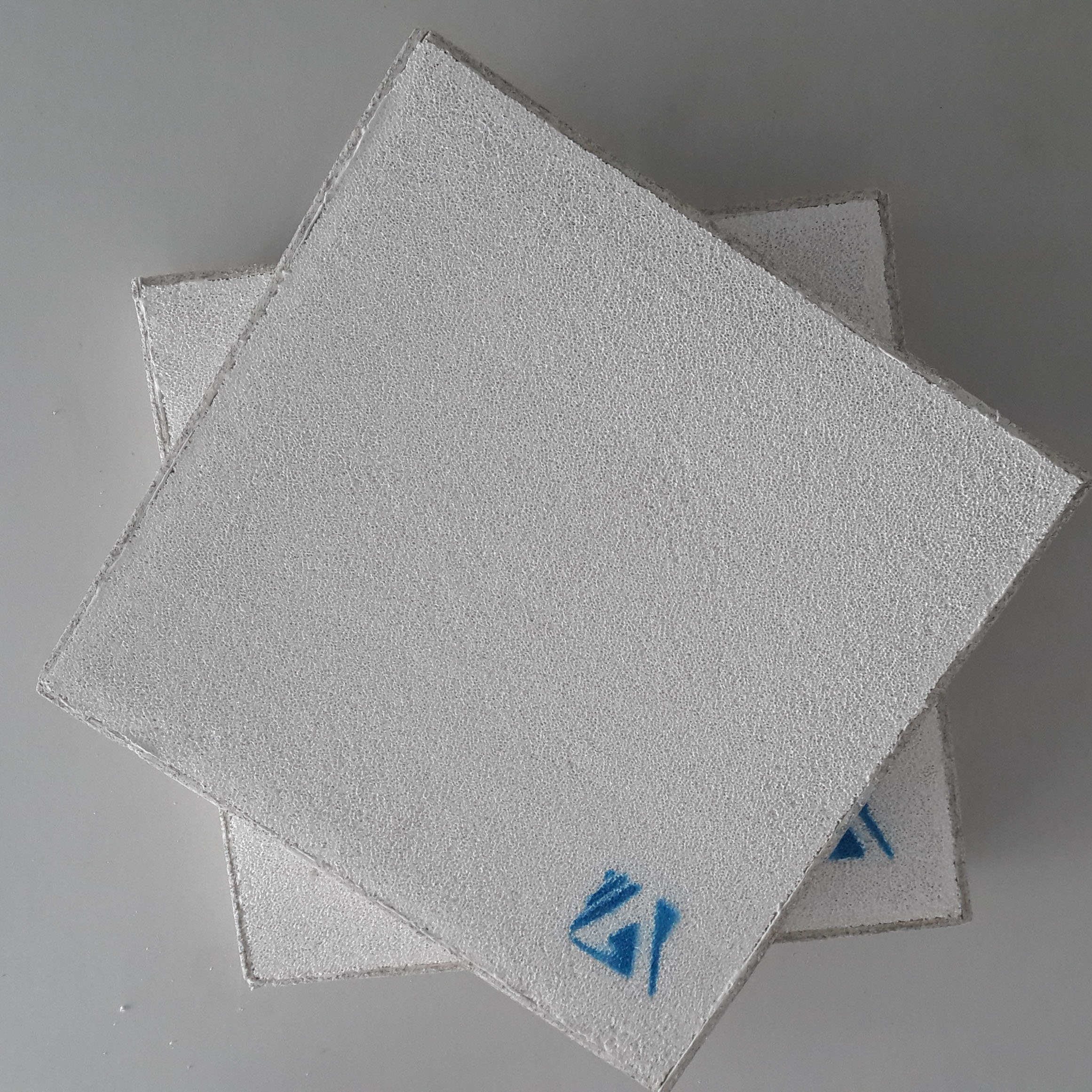

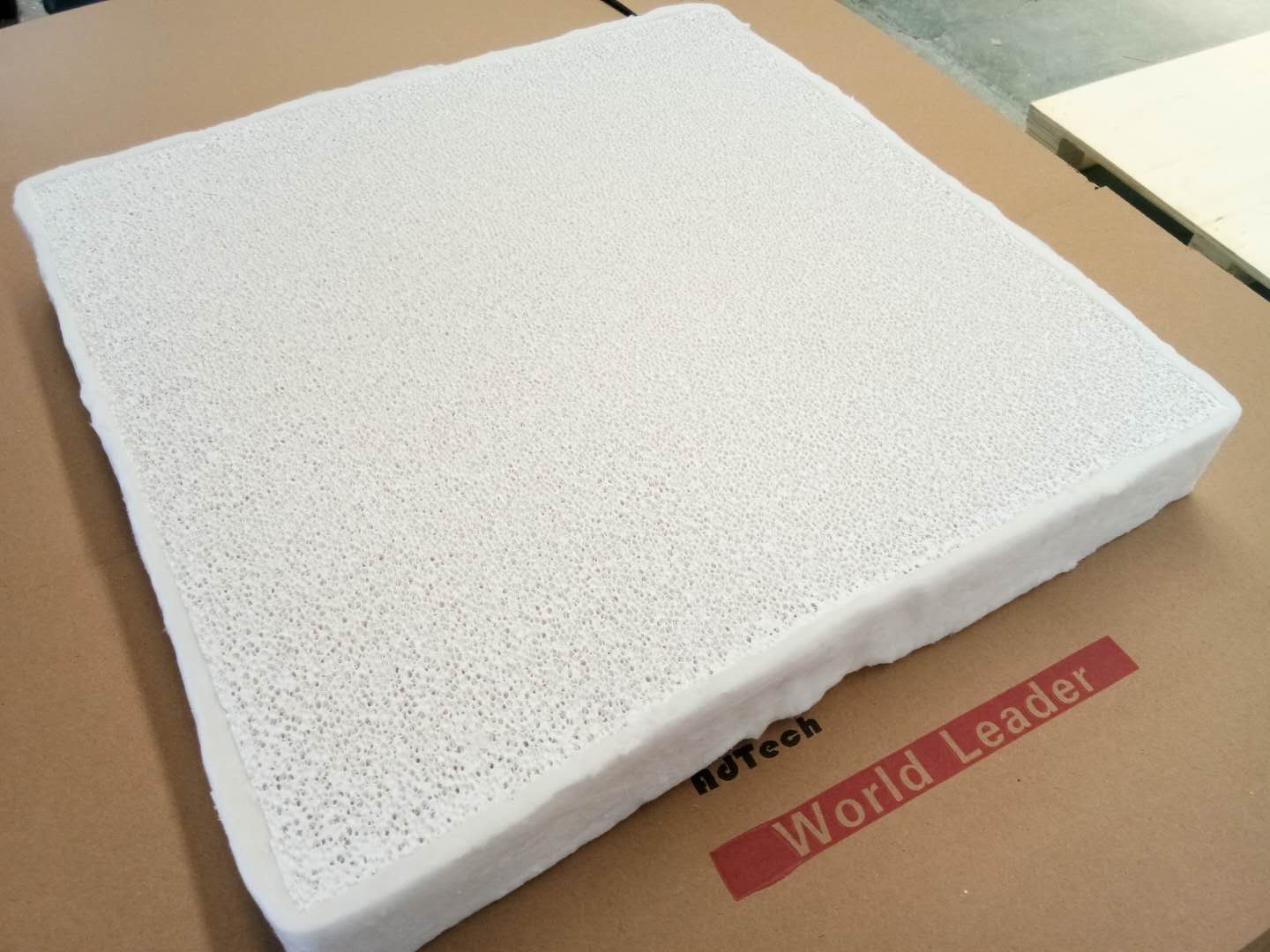

Alu Casting Filter recommended by Dubal Aluminium, which can remove primary and secondary liquid/solid non-metallic inclusions in metal melt.

Simplify the casting system, prevent inclusion defects, improve the mechanical properties of the castings, reduce the machining allowance of the castings, improve the surface finish of the castings, and extend the life of processing tools.

The main inclusions of castings are: slag containing calcium carbonate and iron, manganese, alumina, unmelted inoculant particles, sulfides, magnesium silicate, residual solvents, sand, etc.

In the casting process, Alu Casting Filter can obtain a huge purification effect.

In the pouring process, most of the metal liquid is filled into the cavity in a turbulent state, especially in the initial stage of the pouring, the molten metal enters the cavity from a certain height.

Due to the bending and bending of the flow path of the ceramic foam filter, the rectification ability of liquid metal from turbulent to laminar flow is strong.

The rectification of the filter causes the molten metal, which originally has strong turbulence, to become laminar when passing through the Foam Ceramic Filter.

After passing the Alu Casting Filter, you must pass a longer transition area before returning to the original turbulent state.

In this transition zone, the liquid flow can no longer form turbulence or small turbulence, which avoids the secondary oxidation of the metal and the scrubbing of the mold, thereby preventing the formation of slag and blocking the secondary oxide inclusions.

1. The 1000 series represents 1050 1060 1070 1000 series aluminum plates are also called pure aluminum plates. Among all series, the 1000 series belongs to the series with the most aluminum content. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is currently the most commonly used series in conventional industries. The 1050 and 1060 series are currently mostly circulating on the market. 1000 series aluminum plates determine the minimum aluminum content of this series according to the last two Arabic numerals. For example, the last two Arabic numerals of the 1050 series are 50. According to the international brand naming principle, the aluminum content must reach 99.5% or more to be a qualified product. my country’s aluminum alloy technical standard (gB/T3880-2006) also clearly stipulates that the aluminum content of 1050 reaches 99.5%. Similarly, the aluminum content of 1060 series aluminum plates must reach 99.6% or more.

2.2000 series aluminum plates represent 2A16 (LY16) 2A06 (LY6) 2000 series aluminum plates are characterized by higher hardness, of which the copper content is the highest, about 3-5%. 2000 series aluminum plates are aviation aluminum materials, which are not often used in conventional industries. At present, there are few factories producing 2000 series aluminum plates in my country. The quality cannot be compared with foreign countries. Currently imported aluminum plates are mainly provided by South Korean and German manufacturers. With the development of my country’s aerospace industry, the production technology of 2000 series aluminum plates will be further improved.

3.3000 series aluminum plates represent 3003 3003 3A21. It can also be called anti-rust aluminum plate. my country’s 3000 series aluminum plate production technology is relatively excellent. 3000 series aluminum plate is made of manganese as the main component. The content is between 1.0-1.5. It is a series with better anti-rust function. It is commonly used in humid environments such as air conditioners, refrigerators, and undercars. The price is higher than the 1000 series. It is a more commonly used alloy series.

4.4000 series aluminum plates The representative is 4A01 4000 series aluminum plates belong to the series with higher silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to construction materials, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance Product description: It has the characteristics of heat resistance and wear resistance

5.5000 series represents the 5052.5005.5083.5A05 series. The 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. Therefore, it is commonly used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. The processing technology is continuous casting and rolling, which belongs to the hot-rolled aluminum plate series, so it can be used for oxidation deep processing. In my country, the 5000 series aluminum plate is one of the more mature aluminum plate series.