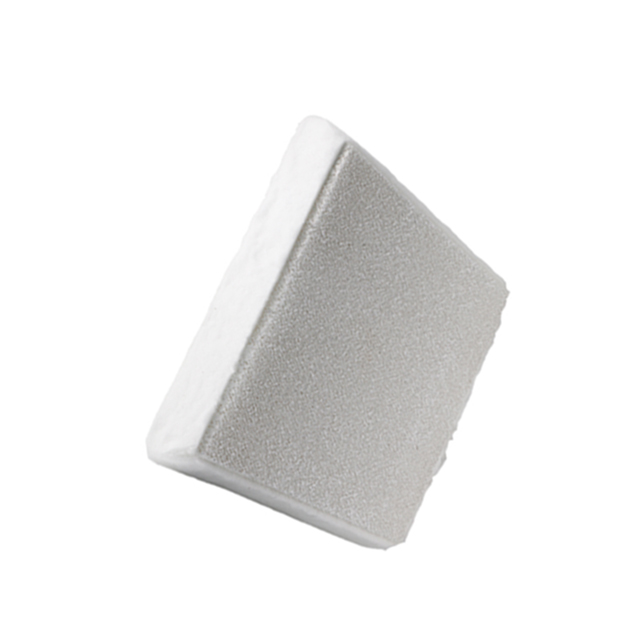

30ppi Ceramic Foam Filter China is composed of many uniform and numerous micropores. When molten aluminum passes through these tiny holes, suspended matter, colloidal particles, and macromolecular organic matter are trapped on the surface of the filter medium, and the fluid passes through the microporous channel to produce various physical effects, achieving the effects of mechanical filtering, purification, diffusion, and fluidization. .

With the development of aerospace and automobile industry, the requirements for the internal quality of aluminum alloy castings are getting higher and higher, but in the process of aluminum alloy melting, refining, heat preservation, alloying and casting, some insoluble inclusions may be brought in, which need to be removed. In order to ensure high-quality aluminum castings.

30ppi Ceramic Foam Filter China is basically divided into 6 pore sizes: 10PPI, 15PPI, 20PPI, 25PPI, 30PPI, and 40PPI.

The larger the number, the smaller the aperture. But in actual practice, the four types of 10PPI 20PPI 30PP 40PPI can meet the needs of customers.

Aperture selection

1. The casting: 10~25ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60p

Rusal Group introduced the advantages of foam ceramic filter plate products

1. Adopt the principle of adsorption to Ceramic Foam Filters For Casting, which can effectively remove large inclusions in molten aluminum, and effectively adsorb small inclusions of micron size. The filtration accuracy of the same mesh size is high.

2. No slag drop, effectively reducing pollution to molten aluminum.

3. Good thermal shock resistance and improved corrosion resistance to molten metal.

Rusal Group is introducing the purchase channel of 30ppi Ceramic Foam Filter China sales@adtechamm.com to the local aluminum casting factory in Russia.

Ceramic Foam Filter instructions

1. Check and clean the debris on the surface of the filter box to keep the filter box clean and free from damage.

2. Gently put the filter plate into the filter box, and press the gasket around the filter plate by hand to prevent the aluminum liquid from flowing or floating.

3. Preheat the filter box and filter plate uniformly to make them close to the temperature of molten aluminum, and the preheat temperature of the filter plate is not less than 260°C. Preheating to remove adsorbed water helps to open the initial filter pore size instantly, and prevents thermal expansion and contraction from causing blockage of the filter plate. Electric or gas heating can be used for preheating. Normal heating is 15-30 minutes.