30ppi Ceramic Foam Filter plays a very important role in the purification system of aluminum alloy casting, which can effectively remove large inclusions in molten aluminum.

It resists the erosion and corrosion of molten aluminum, so it can effectively remove inclusions, reduce the inclusion of gas and provide laminar flow, and the cleanliness of aluminum and aluminum alloys is significantly improved.

Aluminum ingots, aluminum rods and other castings are of high quality, with less waste and fewer inclusion defects.

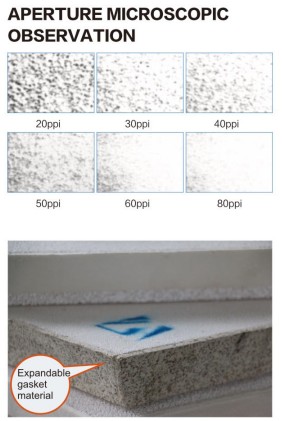

The internationally used ppi means that it means the pore density and pore uniformity of the product. For example, a model of 30ppi means a foam ceramic filter plate product with a pore uniformity of 30 holes on any 25.4mm length.

30ppi Ceramic Foam Filter is used in ordinary aluminum ingot and aluminum rod casting, because these porosities provide a good relationship between filtration capacity and filtration efficiency.

For castings that have high requirements on mechanical strength and/or surface appearance, such as computer hard drives, printed PS bases, manufacturable materials, and fan blades of jet turbine engines, 40-60 ppi ceramic filter plates are recommended.

The main features of ceramic filter plates are as followings

1. Filtration accuracy includes fine filtration, microfiltration, ultrafiltration, nanofiltration, reverse osmosis, and the effect is good.

2. High mechanical strength, stable chemical properties, good wear resistance, low resistance, anti-caking, easy to recoil, easy to clean.

3. High efficiency, high output, beautiful filter mesh arrangement.

Advantages of ceramic filter plate

1. In the process of aluminum casting, filter large inclusions and adsorb small inclusions.

2. No slag, no pollution.

3. Excellent thermal shock resistance and molten metal corrosion resistance.