30ppi 40ppi Casting Filter generally uses polyurethane foam as a carrier, immersed in a ceramic slurry made of fine powders such as refractory aggregate sintering aids, binders, and water, and then squeezes out the excess slurry. The ceramic material around the foam fiber is dried and fired and sintered at a high temperature to finally leave a foamed ceramic product.

Due to the different pouring temperature of the casting alloy, the foam ceramic filter of refractory material should be selected for the casting.

To solve this problem, a simple filter made of wire mesh, steel plate with holes, etc., is inserted into the gating system to remove the inclusions from the beginning.

To the inner filter screen of two-dimensional structure such as silicate pin fiber and boron nitride fiber.

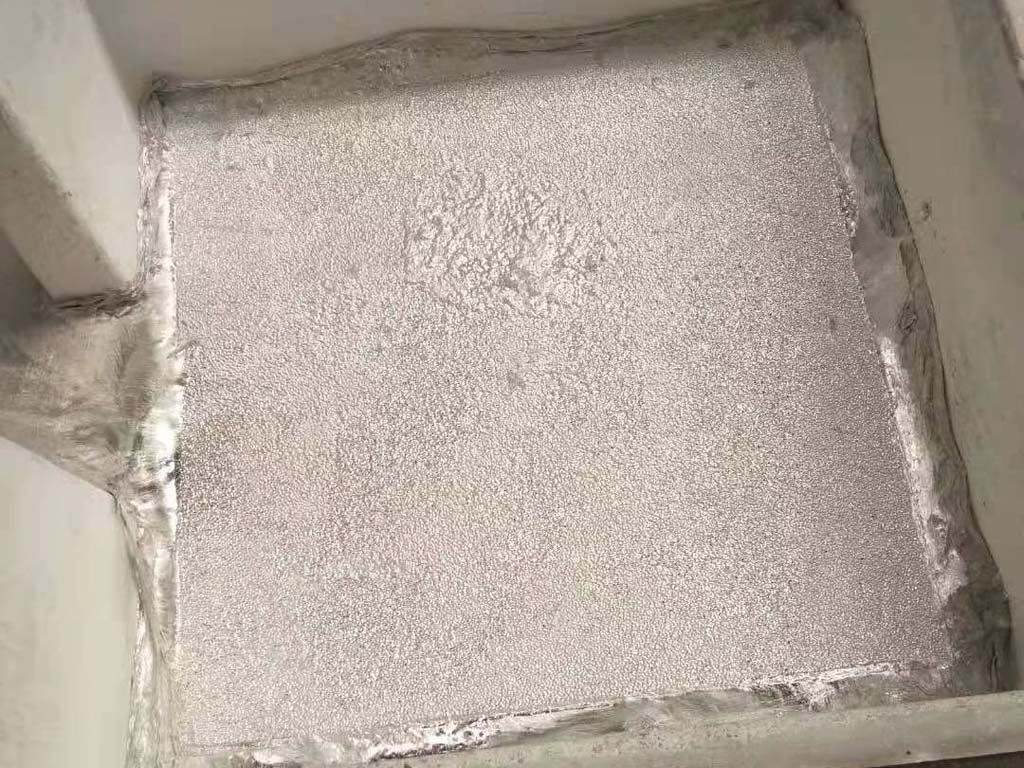

Nowadays, ceramic foam filters use pore size to mechanically intercept large particles of mixed oxides, and use filter cake to filter small particles of mixed oxides.

And with adsorption and rectification capabilities, the production line using foam ceramic filters has significantly improved the yield of castings.

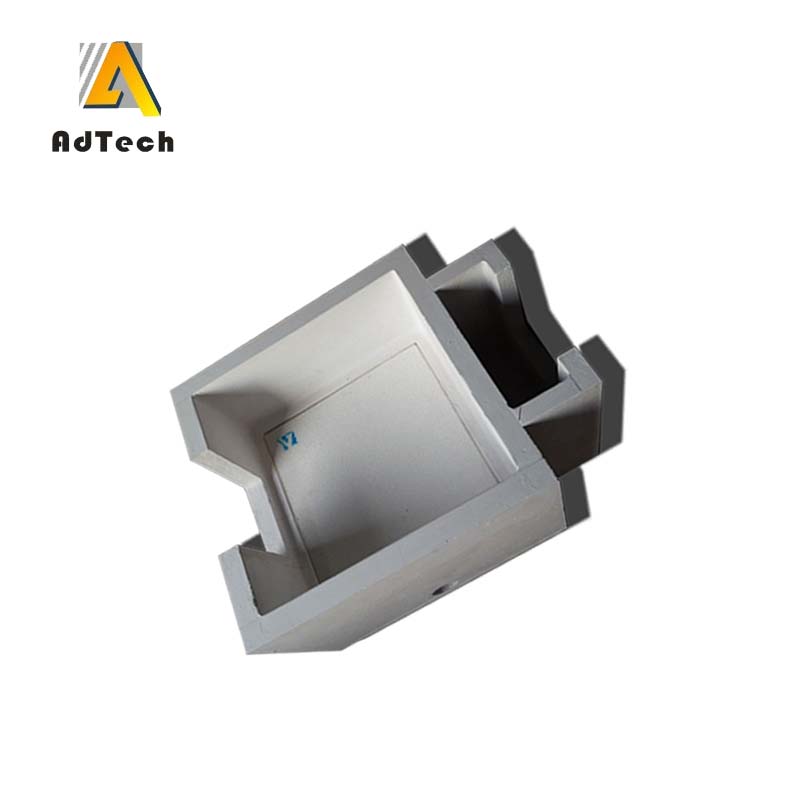

Ceramic foam filter Dimention

660x660x50(26″)

584x584x50(23″)

508x508x50(20″)

432x432x50(17″)

381x381x50(15″)

305x305x50(12″)

228x228x50(9″)

178x178x50(7″)

Ceramic foam fitler Pore Size (PPI): 10/20/30/40/50/60

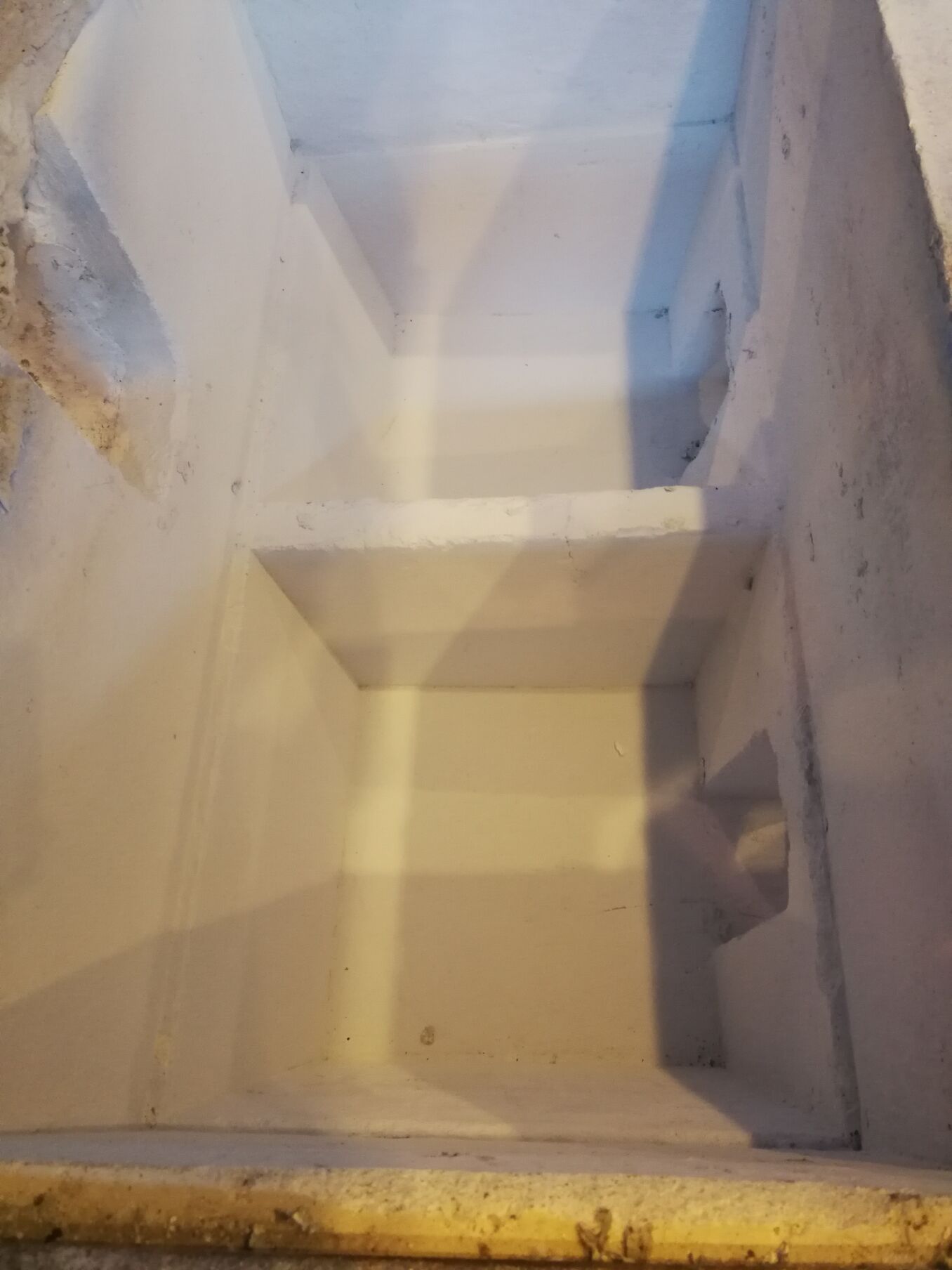

There is an 8mm aluminum silicate liner around the ceramic filter plate to seal the contact part of the filter plate and the filter box to ensure that there is no aluminum liquid bypass.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

30ppi 40ppi Casting Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Foam ceramic filters should be familiar to all engineers in the casting field. Its main function is to eliminate oxidized impurities and other non-metallic inclusions in the casting molten metal by blocking and adsorbing, which can significantly improve the quality of casting parts and reduce the rate of casting waste.

Alumina foam ceramic filter can effectively remove various inclusions in the aluminum water with a fineness of micrometers, so that the aluminum water becomes a smooth laminar flow, which is conducive to punching.

It has good mechanical strength and chemical stability, and excellent aluminum water erosion resistance.

Strictly controlled hole size and through-hole rate can obtain a stable filtering effect; there is a sealing ceramic fiber liner around the foam ceramic filter plate, which helps to seal the filter in the filter box and ensure that there is no metal liquid bypass.