25Ppi Filter Foam

25Ppi Filter Foam has 25 small holes in one square inch. The larger the value, the smaller the hole.

Filter Foam Ppi refers to the number of honeycomb holes on a square inch of Ceramic Foam Filter.

Generally, 15-20 PPI means a large hole, 25-30 PPI is a medium hole, and 35 PPI or more is a small hole.

In the Chinese standard, 25Ppi Filter Foam is not a regular model.

Pore Size(PPI) 20 30 40 50 60

Inclusions Diameter(um)80 40 20 10 5

Filtration Rate(%) 78 85 88 92 95

How to choose the correct Ceramic Foam Filter

If you want 25Ppi Filter Foam, pls contact sales@adtechamm.com

1.There are many impurities, and the quality of cast products is general.

Ceramic filter plates with larger meshes are available, and a glass cloth coarse filter is added in front of the filter plates.

At this time, semi-continuous casting is important for coarse filtration with a glass cloth.

It can intercept the slag from the opening of the eye and the slag washed out by the launder to prevent clogging of the filter plate.

2.The quality of aluminum casting products is high, and the new type of foam ceramics with large mesh size is selected.

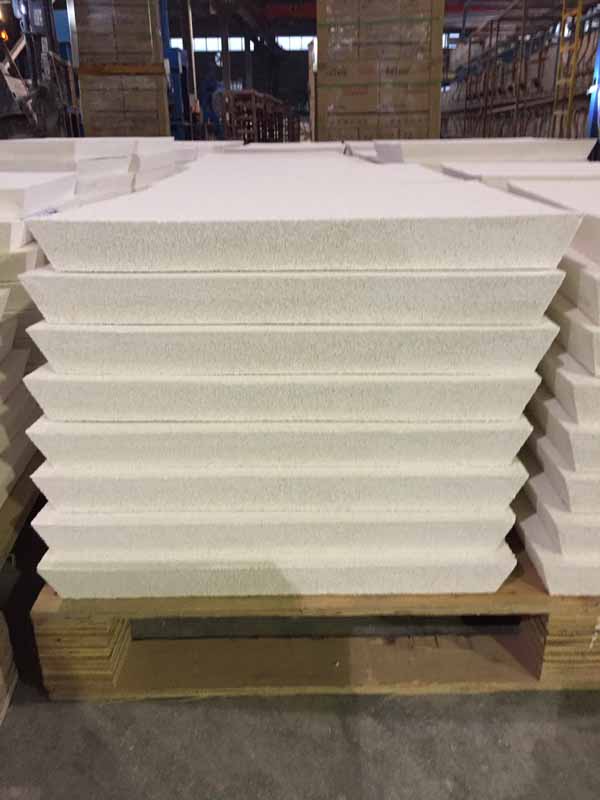

3.The specification of the ceramic filter plate is determined by the flow rate and total throughput of the aluminum melt.

4.The color is pure and no impurity, indicating that the material is uniform; the hand is not sticky, indicating that the surface is not sprayed with adhesive, and will not cause secondary pollution.

5.The effective specific surface area or porosity calculation of the foam should be carefully evaluated when purchasing the filter.

The mesh surface homogenization state of the filter plate can be observed, and then the cross-sectional mesh homogenization state is observed.

If possible, the porosity can be calculated by the drainage method.

The three-dimensional mesh is homogeneous and the porosity is relatively large, which is an excellent ceramic filter plate.

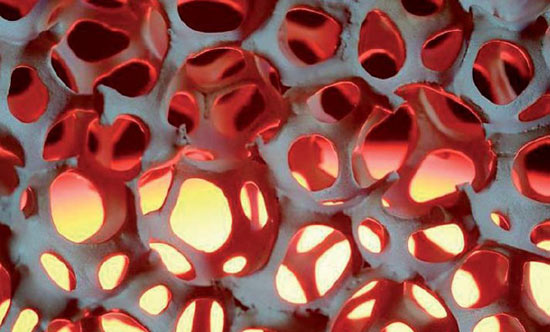

Ceramic Foam Filter transmittance

Transmittance refers to the effective filtration area of the foam ceramic filter plate product. The higher the light transmittance, the less blind holes are, and the more effective the filter holes (potholes), the better the filtering effect.

The foam ceramic filter plate to be inspected is placed on a light box with a built-in 200W incandescent bulb, and the square transparent plastic plate with a uniform 5.0×5.0 mm square is used to measure the area of the large surface of the filter plate, so as to calculate the test. The light transmittance of the filter plate is used to determine the light transmittance of the filter plate. In this standard, the transmittance (through-hole ratio) of the filter plate is specified to be 95% or more.

Ceramic Foam Filter Porosity

Porosity is the percentage of the total volume of the cavities in the filter plate product to the total volume of the filter plate product. Porosity determines the filtration capacity of the foam ceramic filter plate per unit volume. The larger the porosity, the larger the filtration flow rate of the filter plate and the stronger the filtration capacity.

There are currently two main methods for determining porosity.

One is to calculate the volume of the hole in the filter plate according to Archimedes’ law, that is, to inject water into the glass beaker with the overflow pipe until the water flows out from the overflow pipe, and the water will be tested when the water is no longer flowing out. All the samples are gently placed in the water, then the water flows out of the overflow tube, and the volume of water in this part is measured. The volume of the overflow water is subtracted from the physical volume of the filter plate, which is the total volume of the holes in the filter plate. volume.

Another method is to separately determine the true density and bulk density of the sample to be tested, and then calculate the porosity of the sample according to the following formula.

These two methods have their own advantages and disadvantages. The method of operation is simple and convenient, and the detection speed is fast, but its fatal weakness is due to the water absorption characteristics of the filter plate material itself, so that the volume of water discharged is smaller than the actual one. This causes the measured data to be too small.

Although the test process of the second method is more complicated, the influence of the water absorption of the filter plate material is excluded during the test, and the obtained data is relatively accurate.

The index of porosity is determined to be greater than 84% in this standard.