12 Inch Ceramic Foam Filter

At present, in many manufacturing sectors, in particular in the metallurgical foundry areas of industry, highly porous ceramics are in demand – a ceramic material with a porous structure made from highly dispersed mineral powders or from liquid foams.

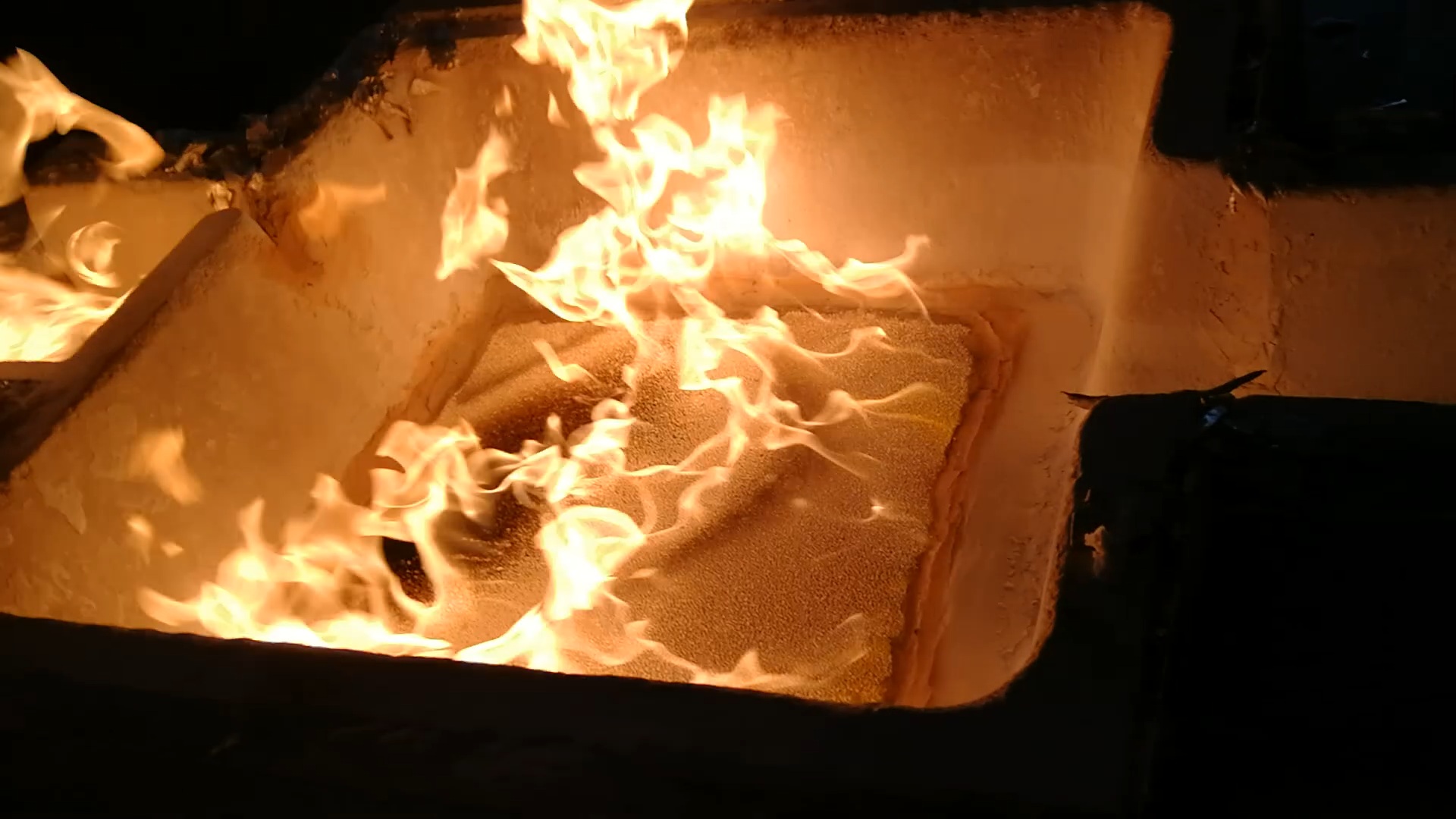

When processing molten metals, it is necessary to remove non-metallic inclusions, such as slag, dross, oxides of starting materials formed on the surface of the molten bath, as well as fragments of refractory materials used to clad a chamber or reservoir in which molten metal is formed.

12 Inch Ceramic Foam Filter due to its low thermal conductivity and high heat resistance is very attractive for use as ceramic foam filters used both in metallurgy for filtering and cleaning metal melts, and in the chemical industry for cleaning high-temperature gas flows.

Ceramic Filter Suppliers Adtech: sales@adtechamm.com

Ceramic foam filters are widely used to separate solids from molten metal.

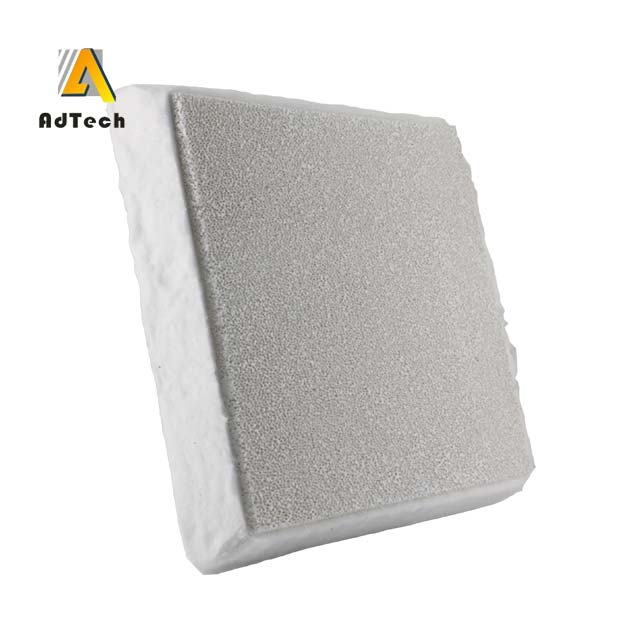

The three-dimensional structure of open pores can significantly improve the quality of filtration.

A homogeneous ceramic structure with a minimum of blocked places on both working surfaces creates optimal conditions for the effective operation of all filtration mechanisms.

Removing inclusions by filtration allows you to create a homogeneous melt and thus improves the quality of products – especially when producing steel, cast iron and aluminum.

The cellular structure of the ceramic foam filter provides deep filtration, which carefully removes a large amount of impurities, without impurities.

The filter is able to withstand significant static pressure of the metal, while maintaining effective filtration. Ceramic foam filters are easily impregnated with molten metal, while the pores act as “traps” for various impurities.