10 Ppi Foam Filter

Various configurations and forms of filters.

They have excellent filtering ability and properties of the constituent materials.

The possibility of using material in many cycles of casting, and, therefore, there is a tangible replacement of disposable filters and metal gratings.

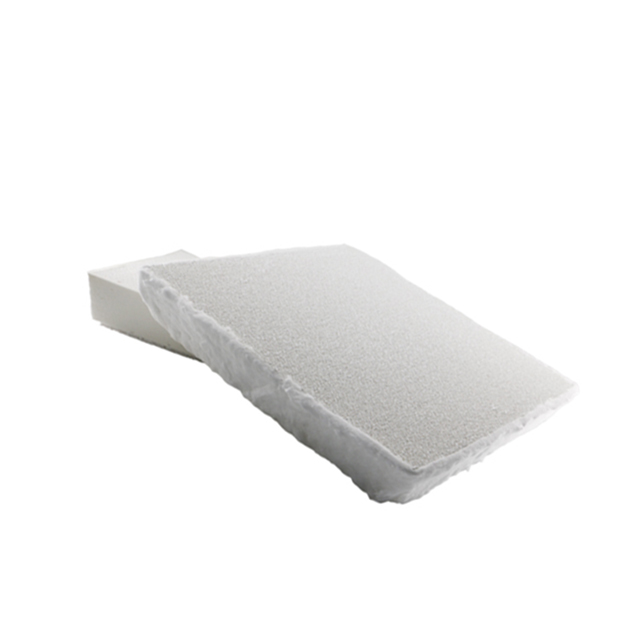

Zirconia based foam ceramic filters

10 Ppi Foam Filter Product benefits

The filter housing has a typical robust ceramic construction and excellent thermomechanical properties, providing excellent stability in operation.

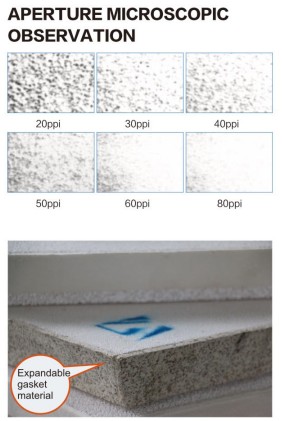

A homogeneous filter structure with a minimum number of clogged sections inside ensures optimal use of the full filter capabilities and uniform passage through the pores during filtration.

Price quality.

High heat capacity of zirconium filters and their suitability for filtering various alloys.

Ideal stability and high mechanical strength.

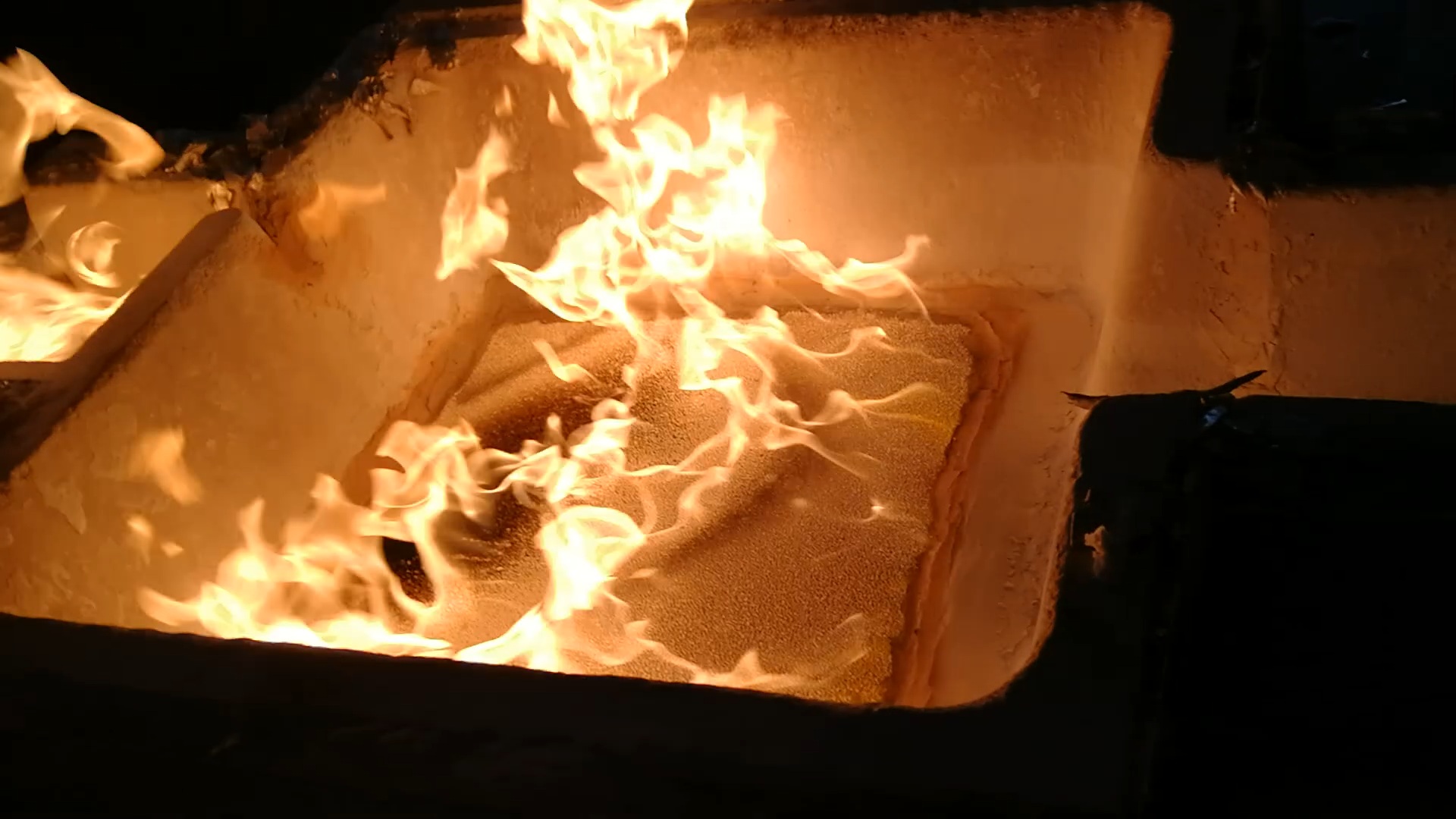

10 Ppi Foam Filter Application

In gating system in special places of installation of the molten aluminium filter

In exothermic glasses or sprue bowls (spilling from above onto the filter).

When casting in a chill mold, with their carousel and linear arrangement.

Silicon Carbide Foam Filters

Ceramic foam filters are designed to filter castings of cast iron, bronze, brass and copper alloys. The maximum recommended application temperature is 1490 ° C.

10 Ppi Foam Filter Product benefits

An open 3D structure of their ceramic matrix formed from a system of interconnected cells.

Good thermal conductivity.

High metallurgical purity.

Good stability and resistance to sudden changes in temperature.

Price quality

Very fast “filling” without negative effects for the metal due to the good chemical properties of the ceramic body.