10-60 Ppi Alumina Ceramic Foam Filter

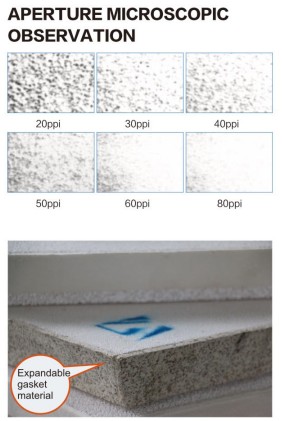

What is the PPI? The PPI just is Pixel Per Inch.

PPI (Pixels Per Inch) – pixels per inch. This indicator is the ratio of the diagonal resolution in pixels to the size of the diagonal in inches.

This PPI calculator has already calculated the width and height of the screen in pixels of your device. It remains only to enter a value indicating the diagonal size of the screen of your monitor.

The PPI calculator will show the pixel density per inch: The higher the value, the more imperceptibly and more naturally the image on the screen looks. In other words, the more pixels fit one inch, the sharper the image you see.

Ceramic foam filters for filtering molten metals

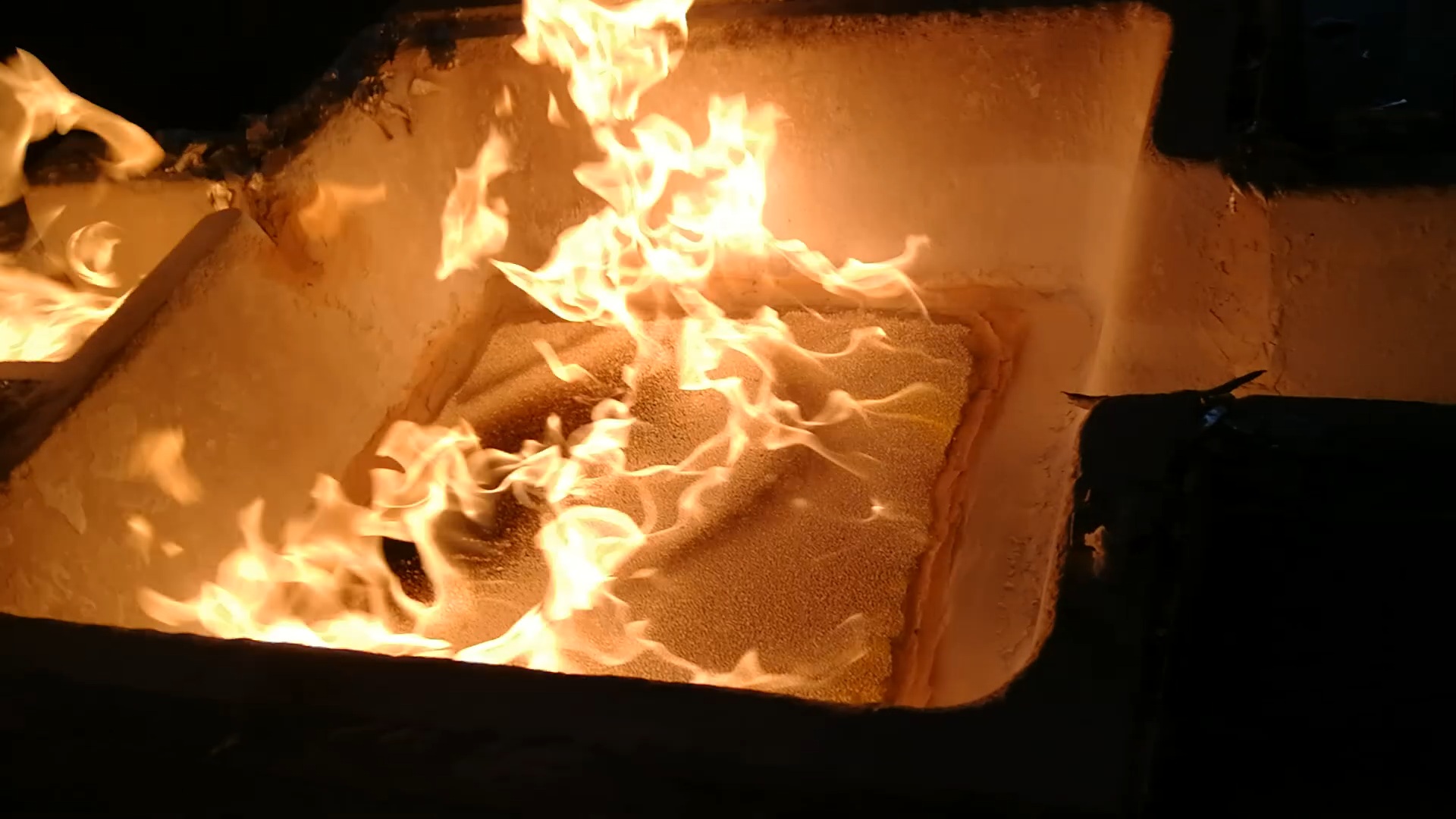

Products of foundry and metallurgical production, claiming a modern level of quality, should have a high degree of purification of the melt during its manufacture. Along with the filtering effect, foamed ceramic filters improve melt flow.

Passing through the filter, the metal flow passes through a system of branched channels. Small particles that did not linger on the filter surface, as they turned out to be too small, continue to move along with the metal flow inside the network of filter channels.

During filtration, the filter channels gradually overgrow, retaining small particles of inclusions. Thanks to this, it is possible to clean the metal from fine particles of impurities contained in the melt. This is of great importance since even the smallest inclusions found in alloy wheels, blanks for making foils or building profiles preclude their further use.

In addition, it was noted that when passing through the ceramic foam filter, the content of gas dissolved in the metal decreases, which also positively affects the further properties of the metal.

The use of filters of various foundry processes explains the wide range of filters produced, which allows us to individually solve the problems of our customers:

alumina ceramic foam filter. Designed specifically for filtering aluminum at temperatures up to 1150ºС

Ceramic Foam filter mainly used for filtering aluminum and aluminum alloys in foundries and cast houses. Due to their excellent heat resistance and corrosion resistance of molten aluminum, they can effectively eliminate inclusions, reduce the clamped gas and provide a laminar flow, and then the filtered Metal is much cleaner. A cleaner metal results in higher quality castings, less scrap and fewer inclusion defects, all of which contribute to bottom-line profits.

10-60 Ppi Alumina Ceramic Foam Filter Advantage

♦ Used to improve the quality of aluminum alloy and other non-ferrous alloy castings

♦ Improve the metallurgical structure

♦ Improve mechanical properties

♦ Change in turbulence in laminar flow

♦ The ambient filter is sealed with an expanded gasket. When the temperature is above 450 ° C, a 200% expansion of the gasket will occur to prevent floating and leakage of Liquid Aluminum through the interface.

♦ The filter can effectively remove large impurities in the molten aluminum and efficiently adsorb tiny impurities.

10-60 Ppi Alumina Ceramic Foam Filter Functions

1. The disinfection of melting metal fluid

2. Simplified navigation system

3. Improving the metallurgical structure of castings

4. Reduce stealth castings

5. Improving casting quality

6. Reduction of internal defects of re-oxidation of castings

7. Reduce surface defects after processing castings

Performance and Applications

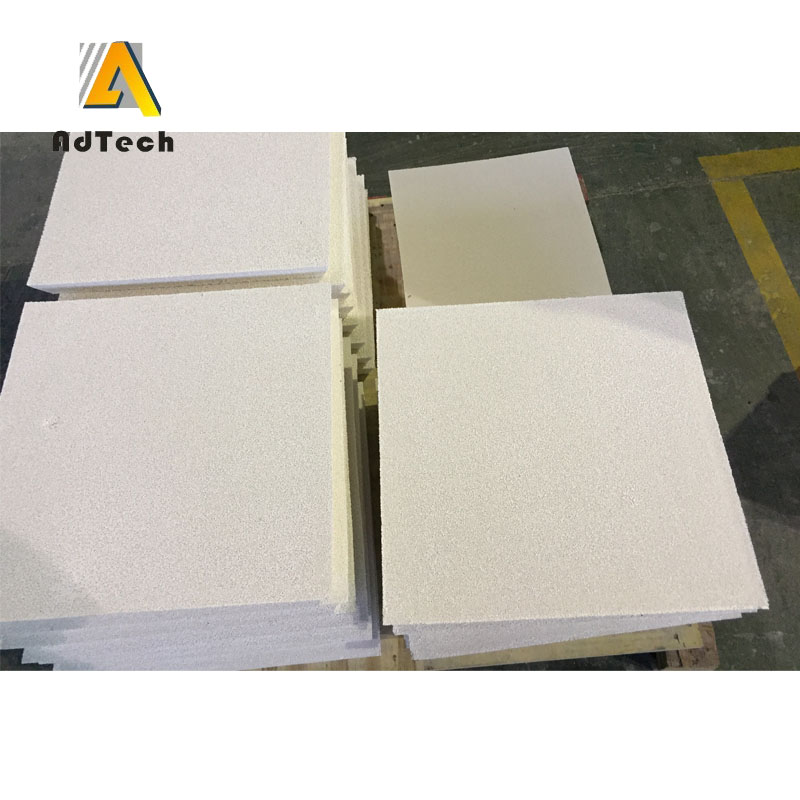

1. Filter-PAL filter is an alumina ceramic product with a three-dimensional network structure through high temperature sintering

2. High strength, erosion resistance, strong adsorption of impurities, can effectively remove tiny inclusions in molten aluminum

3. Widely used in aluminum foil roll casting blanks, production of aluminum and automotive hubs casting blanks

4. Higher applicability and cost-effectiveness