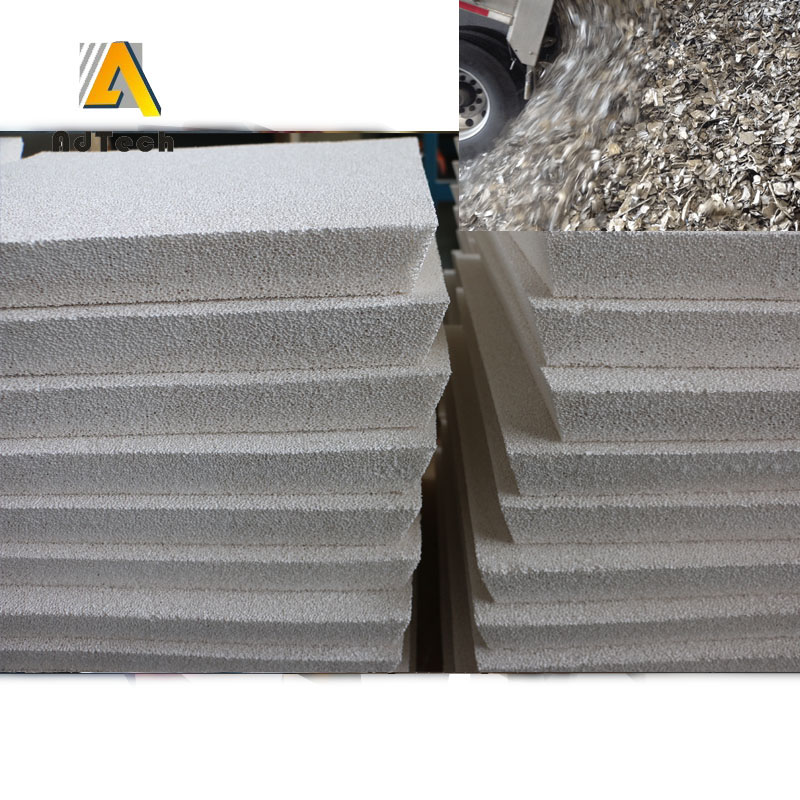

10-50Ppi Alumina Ceramic Foam Filter

10-50Ppi Alumina Ceramic Foam Filter can effectively remove large inclusions in aluminum liquid and adsorb micron-sized fine inclusion particles to improve surface quality, improve product performance, improve microstructure and improve yield.

It is widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys.

10-50Ppi Alumina Ceramic Foam Filter Production Process

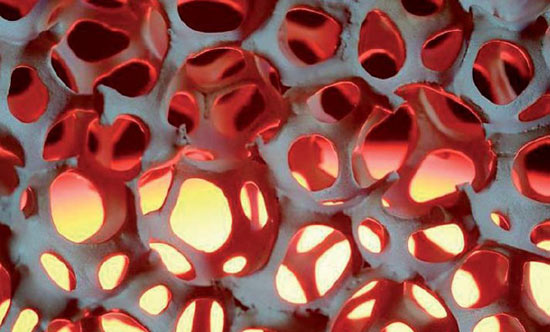

The Ceramic Foam Filter uses a three-dimensional network structure and an organic foam sponge connected to the pores as a carrier, invading it into a special ceramic slurry with thixotropic properties, and adopting a special roll extrusion process to uniformly apply the ceramic slurry to the skeleton of the carrier.

Then, it is dried and solidified and then fired at a high temperature.

Porous Ceramic Foam Filter Foam Ceramic Filters for Aluminum Alloys Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Porous Ceramic Foam Filter uses polyurethane foam as a carrier, immersing it in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruding excess coating to uniformly apply the ceramic coating to the carrier.

The skeleton becomes a green body, and the green body is dried and fired at a high temperature.

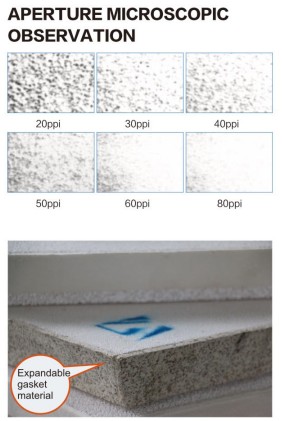

10-50Ppi Alumina Ceramic Foam Filter Pore uniformity

Pore uniformity is used to describe the difference between the number of actual holes per 25.4 mm length in the filter plate product and the number of theoretically required holes.

The smaller the gap, the better the product quality, and the gap is too large, which will result in the ability of the filter plate product to reduce the impurity retention or the slow filtration rate of the melt, which can not meet the individual requirements of the user’s production.

The size of the pore uniformity mainly depends on the foam used in the production of the filter plate. The uniformity of the pores of the foam is good, and the uniformity of the pores of the filter plate is good, so the selection of the foam is extremely important.

The filter 10 PPI means that there are 10 honeycomb holes on one square inch of the filter sponge.

The 30PPI filter sponge has 30 small holes in one square inch. The larger the value, the smaller the hole.

Generally, 15-20 PPI means a large hole, 25-30 PPI is a medium hole, and 35 PPI or more is a small hole.

10-50Ppi Alumina Ceramic Foam Filter has a void ratio of over 97% and an open cell ratio of 99%. It has good gas permeability and high mechanical strength. Therefore, it has the characteristics of low flow resistance and high filtration efficiency.

Filtration Precision for 10-50Ppi Alumina Ceramic Foam Filter

| Pore Size(PPI) | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|

| Inclusions Diameter(um) | 80 | 40 | 20 | 10 | 5 |

| Filtration Rate(%) | 78 | 85 | 88 | 92 | 95 |

Application Data for Ceramic Foam Filter

| Specifications (mm) | Effective filtration area(%) | Filtration flow range(kg/min) |

|---|---|---|

| 7in(178*178*50) | 75 | 22-56 |

| 9in(229*229*50) | 75 | 25-80 |

| 12in(305*305*50) | 80 | 50-156 |

| 15in(381*381*50) | 85 | 85-252 |

| 17in(432*432*50) | 86 | 110-335 |

| 20in(508*508*50) | 88 | 160-478 |

| 23in(584*584*50) | 89 | 210-640 |

| 26in(660*660*50) | 90 | 276-830 |

[…] ceramic foam filter is installed on the CFF BOX machine to filter the liquid impurities of the aluminum alloy to cope […]

[…] Ceramic Foam Filter Iralco Iran can effectively remove the inclusions of the aluminum melt and significantly improve the quality of aluminum products. So as to greatly improve the production of aluminum products. Aluminum products play an important role in the daily lives of residents. In the early production process of aluminum products, due to the imperfection of its own process methods, there was a large amount of aluminum oxide residue in the electrolytic aluminum liquid, which seriously affected the quality of aluminum products. […]

[…] use and selection of Ceramic Foam Filter South Aluminum Iran The ceramic foam filter plate is installed in the filter box between the […]

[…] Ceramic Foam Filter Aluminum Iran is used in the field of aluminum melt filtration. Some domestic and foreign companies have developed from filtering straight-hole honeycomb ceramic plates and ceramic tiles to foam aluminum water filters in the current casting system. […]

[…] Ceramic Foam Filter Iran Aluminium Smelter filters and purifies molten aluminum through diffusion interception, inertial collision interception or screening. The State Key Laboratory of Tsinghua University established a three-dimensional physical model and a two-phase flow model for the filtration mechanism of foam ceramics, and carried out simulation calculations, which is very helpful for us to study the filtration and purification of molten aluminum. However, the process of filtering and purifying molten aluminum by foam ceramics is very complicated, and it is also a complex process of high temperature physical chemistry and metallurgical kinetics. As for screening collision, settlement, interception and filtration, it is better to understand. […]

[…] alumina ceramic foam filter adopts a three-dimensional lattice structure, and uses pore-combined organic foam as a carrier to […]

[…] advantages of Ceramic Foam Filter Maaden Aluminium 1. Using the principle of adsorption, it can effectively remove large impurities […]

[…] Ceramic Foam Filter Mozal Aluminium Plant has been widely used in large aluminum rod and aluminum ingot plants in Africa to obtain relatively clean aluminum ingots and aluminum rods. For the production of industrial and architectural aluminum laminate products, such as ingots or round extrusion ingots, only ceramic casting filters can meet product quality requirements. Single-layer filtration or double filtration can be selected according to product requirements. […]

[…] Filter Bothra Metals The products of ceramic foam filter manufacturers are mainly used for the filtration of cast and cast aluminum and aluminum alloys. It […]

[…] in the aluminum alloy melt and uses the furnace flux to operate. China Aluminum widely uses ceramic foam filter technology outside the furnace. Melting aluminum alloy is the first step in the aluminum alloy […]

[…] Ceramic foam filter Alcoa Aluminum Egypt filters out molten aluminum inclusions larger than the pore size of the filter surface through mechanical separation, and deposits them on the inflow end of the filter liquid metal. […]

[…] Ceramic Foam Filter Iralco has the characteristics of corrosion resistance, high-temperature resistance, high mechanical resistance, no leaching of harmful substances, and no secondary pollution. […]

[…] Filter Pt Indonesia Aluminum is provided by a Chinese manufacturer to sell ceramic foam filters to a local aluminum […]

[…] box is a special aluminum silicate filter box for the aluminum industry. Usually, we call it a ceramic foam filter box, which is made of steel shell and aluminum silicate lining. During the filtration process, the […]

[…] Ceramic foam filter Indonesia Aluminum Company can effectively control the oxidized inclusions in the melt to improve the quality of cast rods and rolled plates have become a common goal pursued by the metallurgical, casting, and material industries of all countries. At present, filtration and purification methods are widely used to remove inclusions in aluminum alloy melts. […]

[…] commonly used size of Molten Aluminum ceramic foam filter Aramit Thai Aluminium Limited is 660x660x50, 584x584x50, 508x508x 50, 432x432x50, 381x381x 50, 305x […]

[…] Aluminum ceramic foam filter Century Extrusion is installed on the CFF box machine to filter liquid impurities in the aluminum […]

[…] of ceramic foam filter to produce aluminum castings Uniform pore size, high porosity, perfect sintering, high bending, […]

[…] Aluminum ceramic foam Filter Jindal Aluminium is mainly used in foundries and foundries to filter aluminum and alloys. The […]

[…] one of the keys to alloying, purification, and refining in the aluminum scrap smelting process. The ceramic foam filter UAE can remove the non-metallic inclusions in the aluminum alloy melt, and adopts the wastewater […]

[…] Ceramic Filter Foundry is an alumina-based ceramic foam filter, which can be widely used for filtering in the casting process of aluminum, aluminum alloy, and […]

[…] Aluminum ceramic foam Filter Kai Aluminium Bd is a filter medium made of high-temperature resistant materials, which chemically […]

[…] Molten Aluminum Filter Aluminum Bangladesh tells you how to choose a ceramic foam filter. […]

[…] Aluminum ceramic foam filter Hind Aluminium is used in the melting process and filtering process of aluminum […]

[…] Ceramic Foam Filter Indonesia Aluminium Smelter is mainly used to filter aluminum and alloys in foundries and foundries. The filter has good resistance to molten aluminum erosion and corrosion, can effectively remove inclusions, reduce trapped gas and provide cleaner laminar flow and filter metal. Cleaner metals can produce higher quality castings, less scrap, and fewer inclusion defects, all of which help increase profits. […]

[…] Aluminum Ceramic Foam Filter Sacheta Metals is mainly used in the aluminum alloy casting industry in civil sectors such as […]

[…] Ceramic foam filter Dimension 660x660x50(26 inch) 584x584x50(23 inch) 508x508x50(20 inch) 432x432x50(17 inch) 381x381x50(15 inch) 305x305x50(12 inch) 228x228x50(9 inch) 178x178x50(7 inch) […]

[…] Ceramic Foam Filter AdTech Ceramic Foam Filter-Packaging quality Each filter plate is packaged in a single cardboard […]

[…] Ceramic Foam Filters AdTech Ceramic Foam Filter-Packaging quality Each filter plate is packaged in a single cardboard […]

[…] ceramic foam filters plate function. * Purification of molten metal liquid * Simple pouring system * Improve the […]

[…] ceramic foam filter plate function. * Purification of molten metal liquid * Simple pouring system * Improve the […]

[…] Ceramic Foam Filter Indonesia Aluminium Smelter is mainly used to filter aluminum and alloys in foundries and foundries. The filter has good resistance to molten aluminum erosion and corrosion, can effectively remove inclusions, reduce trapped gas and provide cleaner laminar flow and filter metal. Cleaner metals can produce higher quality castings, less scrap and fewer inclusion defects, all of which help increase profits. […]

[…] Aluminum Ceramic Foam Filter Aluminium Coimbatore is used to filter molten aluminum. A mesh foam filter that uses alumina […]

[…] between the purification system and the mold table. When the metal is solid, the ability of the ceramic foam filter to capture these inclusions is important to keep the ingot […]

[…] Ceramic Foam Filter Iran is a method that uses porous media (i.e. filter media, such as filter cloth) to separate solids from liquids. Under the influence of the pressure difference on both sides of the filter medium, the liquid passes through the filter medium and becomes a filter. Filter all solid particles remaining on the filter medium, such as filter cake. Through filtration, a filter cake with less water content and Ceramic Foam Filter China without solids can be obtained. Compared with other solid-liquid separation methods, filtration cannot be classified according to the size of solid particles, but it consumes less energy. Since the pores of the filter medium are easily blocked by fine solid particles, the filtration method is more suitable for grouting with larger solid particles or less solid content. […]

[…] Ceramic Foam Filters uses a three-dimensional network structure and organic foam with connected pores as a carrier to […]

[…] Filter is filtering liquid aluminum, the liquid aluminum flows through the tortuous holes of the ceramic foam filters plate. The combined action of force, etc., is retained on the inner surface of the hole of Alumina […]

[…] to Aluminium Japan, purchasing Ceramic Foam Filter Foundry through sales@adtechamm.com can solve the following problems. Avoid the presence of […]

[…] aluminum ceramic foam filter supplier Adtech is from China, email is […]

[…] Ppi Filter Foam, 40/50/60/80 Ppi Filter Foam, ceramic foam filter 20 […]

[…] Group is introducing the purchase channel of 30ppi Ceramic Foam Filter China sales@adtechamm.com to the local aluminum casting factory in […]

[…] ceramic foam filters Jindal Aluminium is mainly used in foundries and foundries to alumina ceramic foam filters and alloys. The ceramic foam filter has excellent resistance to molten aluminum erosion and […]

[…] with flux powder, and the foam ceramic plate is used for filtering outside the furnace. The ceramic foam filter plate is to be replaced every time it is cast. A trough-type online degassing unit is added at the […]

[…] can use the lowest-cost ceramic foam filters because the melting point of aluminum is very low for […]

[…] network structure and an organic foam body connected to pores as a carrier; 2. The zirconia ceramic foam filter invades the special ZrO2 molten material with thixotropy; 3. The zirconia ceramic foam filter […]

[…] Ceramic Foam Filter is a method that uses porous media (i.e. filter media, such as filter cloth) to separate solids from liquids. Under the influence of the pressure difference on both sides of the filter medium, the liquid passes through the filter medium and becomes a filter. Filter all solid particles remaining on the filter medium, such as filter cake. Through filtration, a filter cake with less water content and Ceramic Foam Filter China without solids can be obtained. Compared with other solid-liquid separation methods, filtration cannot be classified according to the size of solid particles, but it consumes less energy. Since the pores of the filter medium are easily blocked by fine solid particles, the filtration method is more suitable for grouting with larger solid particles or less solid content. […]

[…] Under the action of gravity and pressure, the molten aluminum passes through the pores of the Ceramic Foam Filter and the solid particles are intercepted, so as to achieve the purification of the aluminum […]